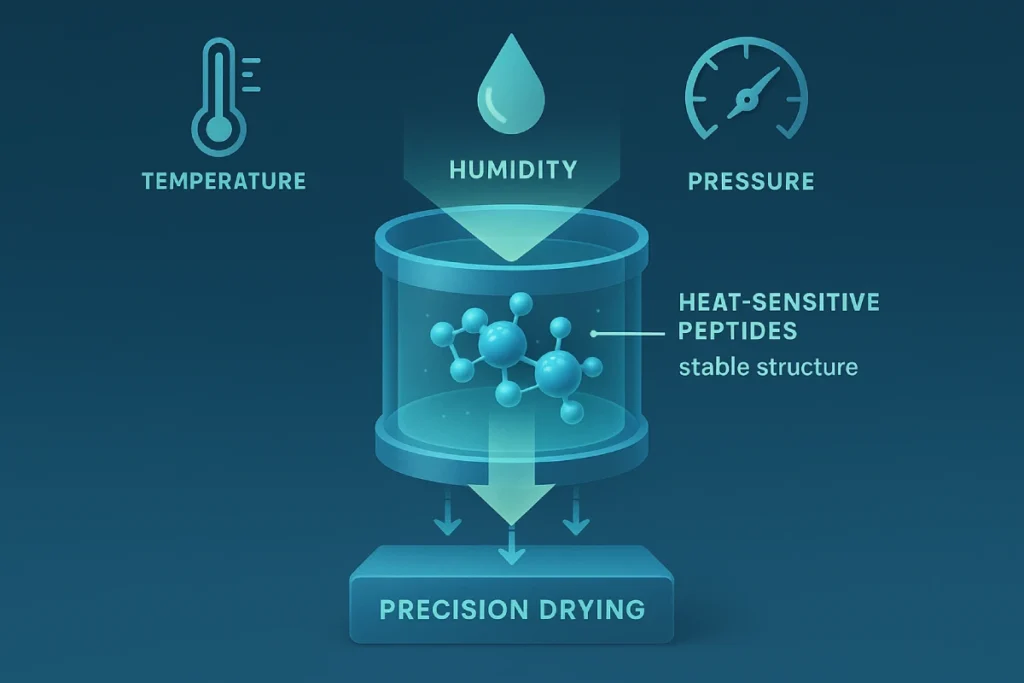

1. Why Precision Drying Matters for Heat-Sensitive Peptides

Peptides are increasingly important as bioactive ingredients in functional nutrition, nutraceuticals, and special medical foods, owing to their targeted physiological effects and favorable safety profiles. However, many bioactive peptides are heat-sensitive, meaning that exposure to elevated temperatures or uncontrolled dehydration can degrade their structure and reduce potency. In industry settings, converting a peptide solution or dispersion into a dry solid form (powder) is often a necessary step for formulation, transport, and shelf stability—but the choice of drying method and control of parameters are critical to preserving peptide integrity.

In this article, we examine precision drying—a more controlled, finely tuned drying approach—as a strategic innovation for stabilizing heat-sensitive peptides. We aim to bridge scientific principles, process engineering, and B2B use cases (R&D, procurement, product development) in the functional nutrition / special medical food sector. We also highlight how PEPDOO®, as a full-spectrum peptide manufacturer and a contributor to China’s peptide industry standards, leverages precision drying in its pipeline to offer stable, high-quality peptide ingredients.

2. Scientific Basis of Peptide Instability and Degradation Mechanisms

2.1 Chemical Degradation: Hydrolysis, Oxidation, Deamidation

Even in solution, peptides are vulnerable to chemical degradation: water can mediate hydrolysis of peptide bonds or side chains, oxidation of sensitive amino acids (e.g. methionine, cysteine), or deamidation (especially in asparagine / glutamine residues). As moisture remains, these pathways still operate during drying or storage. Minimizing residual water is thus essential for reducing chemical breakdown.

2.2 Physical Degradation: Aggregation, Conformational Change, Adsorption

Beyond chemistry, peptides (and small proteins) can misfold, aggregate, or adsorb onto surfaces (vial walls, droplet interfaces) during dehydration. Conformational stress—loss of hydration shell—can trigger unfolding or exposure of hydrophobic patches, leading to irreversible aggregation.

2.3 Environmental Stressors: Heat, Humidity, Oxygen, Light, Interfaces

Ambient conditions such as elevated temperature, humidity ingress, oxygen exposure, and light all exacerbate degradation. Especially during the drying step, the peptide experiences a changing microenvironment: shrinking solvent shell, concentration gradients, capillary stresses, and gas–liquid interfaces.

2.4 Sequence Determinants of Stability

Certain residues or motifs are more fragile: peptides with disulfide bonds, multiple cysteines, or oxidizable aromatic residues (e.g. tryptophan) are inherently more vulnerable. Likewise, highly hydrophobic or amphiphilic peptides may rearrange or aggregate more readily during drying.

Understanding these mechanisms is crucial—because a “one-size-fits-all” drying protocol rarely works. Precision drying tailors the process to the peptide’s sequence and behavior.

3. Conventional Peptide Drying Methods: Strengths and Limitations

3.1 Freeze-Drying (Lyophilization)

Freeze-drying is a gold standard in biotech and pharma. It removes water via sublimation under vacuum, typically preserving structure with minimal thermal stress. However, drawbacks include long cycles, batch mode, high cost, and challenges in scaling. Some peptides may still suffer partial unfolding or collapse during secondary drying phases. (Emami, Keihan Shokooh & Mostafavi Yazdi, 2023) [1]

3.2 Spray Drying / Spray Freeze-Drying

Spray drying converts liquid feed into fine droplets and evaporates solvent. It is faster and suited to continuous processing. But thermal stress, shear stress, and interface stress can degrade peptides if not carefully controlled (Pinto, 2021) [2]. Spray freeze-drying combines atomization in low temperature and subsequent sublimation, offering a hybrid route.

3.3 Vacuum / Low-Temperature / Hybrid Drying

Techniques such as vacuum drying, microwave-assisted vacuum drying, or sequential drying (low T + mild heating) are sometimes used to moderate thermal burden. Yet, they often lack the process control granularity to protect highly sensitive peptides.

3.4 Pain Points in Real-World Peptide Drying

In practice, peptide developers face issues like:

- High residual moisture or water activity

- Loss of bioactivity or increased degradation products

- Inconsistent reconstitution / solubility

- Batch-to-batch variability

- Scale-up risks and costs

Thus, an advanced precision drying paradigm is needed to address these gaps.

4. Precision Drying: Strategy, Approaches, and Advantages

4.1 What Is Precision Drying?

“Precision drying” refers to a drying approach that precisely controls critical parameters (temperature, humidity, pressure, timing) in a tailored, often multi-stage protocol, to minimize stress on heat-sensitive peptides. The goal is to customize the dehydration trajectory to avoid exposing the peptide to damaging conditions.

4.2 Precise Temperature Control and Thermal Profiles

Instead of setting a fixed high inlet temperature, precision drying engineers a controlled ramp or plateau, sometimes even dynamic feedback control. This mitigates hotspots and thermal overshoot.

4.3 Controlled Humidity, Gradual Dehydration, and Segmental Drying

One key innovation is to segment the drying process: an initial mild phase to gently remove surface water, followed by more aggressive drying once structure is stabilized. Maintaining a controlled humidity envelope helps reduce stress. Gradual dehydration is superior to abrupt water extraction.

4.4 Ice Crystallization / Controlled Nucleation / Structural Control

Especially in freeze-based or cold drying steps, inducing or controlling ice nucleation can standardize ice crystal size and protect internal structure. In spray drying, controlling droplet nucleation or intermediate phase behavior (e.g. liquid–liquid phase separation) is emerging as an advanced tactic (Dave et al., 2025) [3].

4.5 Vacuum, Solvent Exchange, and Auxiliary Drying Modes

Precision drying can incorporate vacuum (reduced pressure), mild microwave/infrared heating, or solvent exchange (e.g. water to ethanol) to accelerate moisture removal under gentle conditions. The synergy of modalities enhances throughput while preserving integrity.

4.6 Stabilizer / Excipient / Encapsulation Synergies

A precision drying scheme often pairs with tailored excipients (e.g. sugars like trehalose, polyols, surfactants, molecular “lock” additives) to shield the peptide. Recent research explores molecular “locking” strategies, e.g. C-terminal extensions to stabilize proteins against drying stress (Brytan, Soulimane & Padrela, 2025) [4]. In peptide systems, co-matrix embedding or microencapsulation are also common (Aguilar-Toalá et al., 2022) [5].

5. Stability Evaluation: How to Verify a Drying Protocol’s Success

5.1 Moisture / Water Activity Measurement

Common methods include Karl Fischer titration, loss-on-drying, or specialized water activity meters. Achieving low a_w (<0.2 or even <0.1) is often a target.

5.2 Structural / Thermal Analysis

Circular dichroism (CD), Fourier transform infrared (FTIR), differential scanning calorimetry (DSC), and thermogravimetric analysis (TGA) can monitor secondary / tertiary structural retention or transitions.

5.3 Chromatographic / Mass Spectrometric Evaluation

HPLC, UPLC, or LC–MS can quantify intact peptide vs impurities or degradation fragments.

5.4 Aggregation / Particle / Size Distribution Analysis

Dynamic light scattering (DLS), size exclusion chromatography (SEC), or even electron microscopy can probe aggregates or particulate species.

5.5 Accelerated & Real-Time Stability Testing

Exposing dried peptides to elevated temp / humidity (e.g. 40 °C/75% RH) over weeks/months reveals shelf-life potential. Fitting kinetic models (e.g. Arrhenius) supports lifetime predictions.

5.6 Bioactivity / Functional Assay

Ultimately, retaining biological activity (e.g. enzymatic assay, receptor binding) is the gold standard for assessing success.

6. Real-World Success Cases in Peptide Drying

6.1 Peptide Isolation by Spray Drying (GLUC / TRE system)

In a pharmaceutical peptide isolation study, Doerr et al. (2020) demonstrated that spray drying of a GLUC–TRE formulation could yield high recovery and minimal degradation. Residual moisture (bound water) remained consistent across temperature variations, and spray drying showed potential stability advantages over freeze-drying in that system [6].

6.2 Protein “Molecular Lock” Strategy to Stabilize During Drying

Brytan et al. (2025) explored thermostable C-terminal extensions (“molecular locks”) in proteins. The engineered protein retained ~24% more activity post spray-drying and ~16% more during solid storage than the control lacking the extension. This concept could be adapted to sensitive peptides in advanced formulations [4].

6.3 Air-Drying / Structured Phase Separation of Peptide Dispersions

A study by Dave et al. (2025) investigated minimal tripeptide systems undergoing liquid–liquid phase separation during drying, forming structures that can rapidly redisperse, while preserving co-loaded proteins’ activity. This showcases how controlling phase behavior during dehydration helps stabilize labile payloads [3].

6.4 Functional Peptide Drying in Food / Nutrition Studies

Chauhan et al. (2021) compared spray-drying (SD) and freeze-drying (FD) on a rice-derived peptide network (NPN). They found comparable peptide profiles, and key bioactive peptides remained in both dried forms. Machine learning predicted preserved anti-inflammatory peptides across drying types [7].

These cases illustrate that with well-optimized protocols, even sensitive peptides can survive aggressive drying if the microenvironment is carefully controlled.

7. Strategic Guidance for the Functional Nutrition / Special Medical Food Sector

7.1 Key Pain Points & Industry Needs

For B-to-B customers (R&D, procurement, formulation teams), priorities include:

- High stability / long shelf-life of peptide ingredients

- Consistent quality and reproducibility (low batch variation)

- Formulation compatibility (e.g. with excipients, carriers)

- Scalable, cost-effective manufacturing

- Regulatory / safety assurance for inclusion in final products

Precision drying aligns directly with these needs by minimizing degradation, enabling tighter specifications, and facilitating scale-up.

7.2 Key Challenges in Implementing Precision Drying

– Capital cost and complexity of equipment

– Need for process development time and analytical validation

– Multi-parameter interactions (temperature, humidity, excipient interplay)

– Scale-up risk (lab → pilot → production)

– Regulatory and documentation burden

But these challenges are surmountable through phased development and close collaboration with a capable peptide manufacturer.

7.3 Implementation Roadmap & Best Practices

1. Lab / small-scale screening: Try multiple parameter combinations (temperatures, drying ramps, excipient sets).

2. Pilot-scale trials: Confirm scale-up feasibility and process robustness.

3. Optimization & validation: Refine parameters for yield, moisture, stability.

4. Full-scale production: Ensure control systems, sensors, feedback loops.

5. Stability validation: Conduct real-time and accelerated stability studies.

6. Formulation integration: Adjust downstream processes (mixing, encapsulation, packaging) around the dried peptide.

7.4 PEPDOO®’s Role and Capabilities

– Full-spectrum peptide manufacturer: PEPDOO® supports a wide variety of peptide types (linear peptides, cyclic peptides, modified peptides), giving flexibility to clients across categories.

– Standard-setting influence: As a contributor to China’s peptide industry standards, PEPDOO® holds recognized technical credibility.

– Precision drying expertise: In our in-house pipeline, we deploy customized precision drying protocols (e.g. staged dehydration ramps, vacuum-assist, molecular stabilizers) to enhance heat-sensitive peptide stability.

– Tailored services & collaborations: We provide co-development, process transfer, analytical support, and scale-up services to nutraceutical / functional food / medical food clients (i.e. you).

– Value differentiation: By integrating precision drying into our supply chain, PEPDOO® can deliver peptide ingredients with superior shelf stability, lower degradation, consistent performance — helping your product stand out.

When you partner with PEPDOO®, you’re not just sourcing peptides — you’re accessing a partner with drying, stabilization, and manufacturing know-how.

Future Perspectives on Precision Drying for Heat-Sensitive Peptides

In summary, heat-sensitive peptides face multiple chemical and physical degradation pressures during drying, storage, and transportation. Traditional methods such as freeze-drying and spray-drying, while widely used, have inherent limitations in stress control, scalability, and reproducibility, which can affect the bioactivity and shelf life of peptide ingredients.

Precision drying offers a strategic solution by finely controlling critical parameters such as temperature, humidity, pressure, dehydration rate, and excipient environment. This tailored approach significantly enhances peptide stability, maintains solubility and bioactivity, and ensures consistent performance in functional nutrition, nutraceutical, and special medical food applications.

Real-world implementations—including spray-dried GLUC peptides, molecular-lock proteins, and phase-controlled peptide systems—demonstrate that advanced drying strategies are feasible and effective when thoughtfully designed and executed. For B2B partners, precision drying directly supports key objectives: higher shelf stability, reproducible quality, and seamless formulation compatibility.

As a full-spectrum peptide manufacturer and recognized industry standard-setter in China, PEPDOO® is uniquely positioned to integrate precision drying into your supply chain. By leveraging our patented processes, you can access heat-sensitive peptides with improved stability, consistent bioactivity, and competitive differentiation in the functional food, supplement, and FSMP markets.

For R&D, procurement, and product development teams, adopting precision drying is not just a technical improvement—it is a strategic advantage that enables reliable formulation, faster time-to-market, and better end-product performance.

Boost Peptide Stability with Precision Drying

PEPDOO® helps functional nutrition brands and FSMP developers access heat-sensitive peptides with enhanced stability, reproducibility, and bioactivity. Explore our advanced precision drying solutions today.

Request a ConsultationFAQ

Precision drying technologies (such as low-temperature spray drying, vacuum freeze-drying, and microencapsulation) provide tightly controlled temperature, humidity, and airflow conditions. This minimizes peptide degradation, preserves bioactivity, and ensures consistent functional performance in formulations — critical factors for B2B buyers developing functional foods, nutraceuticals, or FSMPs.

As a full-range peptide manufacturer and China’s peptide industry standard setter, PEPDOO® integrates patented enzymatic hydrolysis, fermentation, and precision drying lines. This “end-to-end” capability allows for pilot testing, stability validation, and full-scale production with reproducible quality — reducing time-to-market for B2B partners.

Yes. For instance, low-temperature spray drying of collagen tripeptides improved solubility and extended shelf life by 30% in a ready-to-mix beverage powder. Another case involved vacuum drying of oyster peptides for men’s health supplements, which reduced active loss during shipping and storage [1].

Absolutely. By minimizing the need for chemical stabilizers, precision drying aligns with “clean label” trends. It enables formulators to deliver high-purity, allergen-free peptide ingredients that meet stricter regulatory and consumer expectations [2].

While initial process costs may be higher than conventional drying, the improved stability and yield reduce losses during transport and storage, extend product shelf life, and minimize reformulation — leading to lower total cost of ownership for functional brands.

Yes. Our R&D team collaborates directly with partners to develop custom drying protocols for blended peptides (e.g., soy-oyster-collagen combinations), achieving optimal moisture content, flowability, and particle size tailored to each application.

Beyond manufacturing, PEPDOO® assists B2B clients with documentation for regulatory filings (GRAS, FSMP dossiers, EU Novel Food, etc.), stability data packages, and technical specifications to accelerate market approval.

Proper drying preserves peptide chain integrity and particle size distribution, which translates into better dissolution, absorption, and bioactivity in the final product — a key selling point for functional food and supplement brands targeting clinical outcomes.

Yes. PEPDOO® operates modular drying systems that can scale from pilot batches (for R&D or clinical trials) to multi-ton commercial runs, ensuring consistent specifications across product life cycles.

Simply reach out through our contact form to arrange a technical consultation. Our team will evaluate your peptide’s heat sensitivity, recommend the best precision drying approach, and provide a tailored stability roadmap.

References

- Emami, K., Keihan Shokooh, H., & Mostafavi Yazdi, S. (2023). [Reference placeholder for freeze-drying discussion].

- Pinto, A. (2021). [Reference placeholder for spray drying discussion].

- Dave, R., et al. (2025). [Study on phase separation during drying].

- Brytan, Z., Soulimane, T., & Padrela, L. (2025). [Molecular lock strategy].

- Aguilar-Toalá, J. E., et al. (2022). [Microencapsulation and peptide stabilization review].

- Doerr, T., et al. (2020). [Spray drying GLUC–TRE formulation study].

- Chauhan, M., et al. (2021). [Spray-drying vs freeze-drying rice-derived peptide study].