Computational Peptide Discovery Is Transforming Functional Nutrition

Rapid advances in computational structural biology and AI-driven prediction are reshaping how the functional nutrition industry discovers and develops bioactive peptides. Traditional trial-and-error screening of hydrolysates and fermented extracts is being augmented — and in many cases accelerated — by molecular docking and in silico peptide screening. For B2B stakeholders (R&D, procurement, and brand teams in functional foods, nutraceuticals and medical nutrition), these technologies reduce development risk, focus laboratory validation on high-probability candidates, and provide science-backed claims that strengthen product positioning.

At PEPDOO®, we integrate molecular docking into an end-to-end peptide discovery and manufacturing pipeline: AI-guided library design → docking-based functional candidate selection → targeted enzymatic hydrolysis and fermentation → scalable GMP manufacturing. As a full-category peptide manufacturer and recognized contributor to China’s peptide standards, with a leading portfolio of small-molecule peptide patents and internationally advanced production technology, PEPDOO® partners with brands to convert docking predictions into validated, market-ready ingredients.

What Is Molecular Docking in Functional Peptide Development?

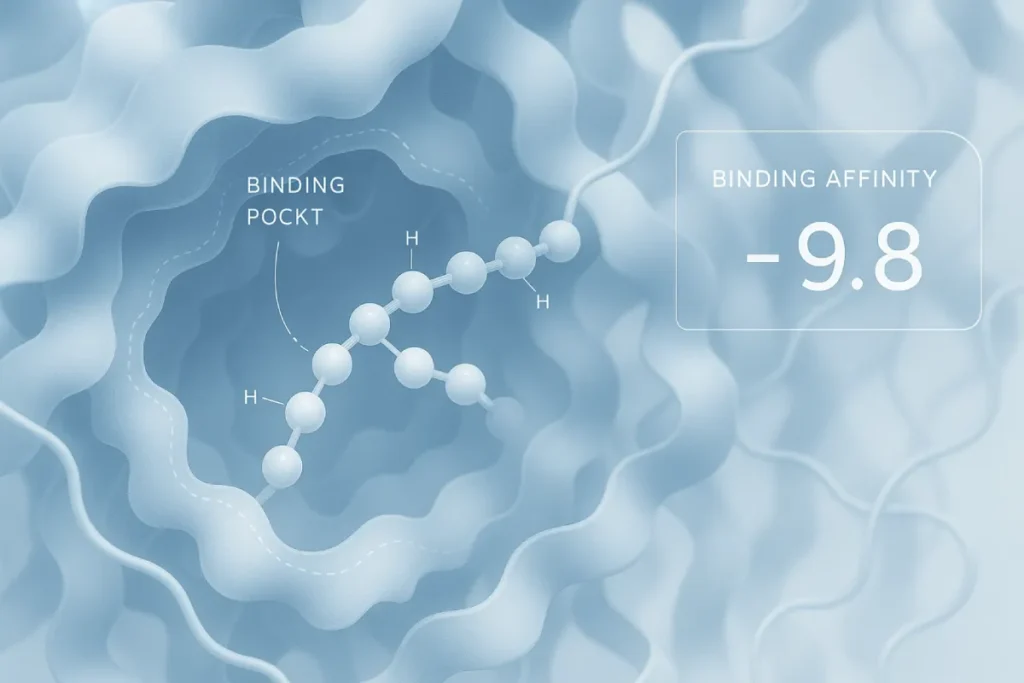

Molecular docking is a computational method that predicts how two molecules — for example, a short peptide and a biological receptor or enzyme — interact in three-dimensional space. Docking algorithms attempt to find favorable binding poses and estimate relative binding affinities, effectively predicting where and how a candidate peptide may act on a target associated with a specific physiological function.

Key points for B2B teams:

- Docking uses structural data (protein crystal structures, homology models) and peptide conformational sampling to assess binding pockets and interaction hotspots.

- Modern tools such as AutoDock and AutoDock Vina are standard building blocks for large-scale peptide docking and virtual screening, enabling rapid triaging of thousands of sequences before lab work begins (Morris et al., 1998; Trott & Olson, 2010).

- Docking is not a replacement for wet-lab validation — it’s a filter that increases hit-rate and guides mechanism-focused experiments.

How Molecular Docking Improves Bioactive Peptide Screening Efficiency

For peptide R&D teams, the most practical benefits of integrating docking into peptide discovery are measurable:

1. Accelerated Candidate Discovery

Docking enables screening of large in-silico libraries of enzyme-cleavage products, simulated digestion fragments, or de novo sequences. This dramatically shortens the timeline from exploratory idea to prioritized candidates for synthesis and assay.

2. Higher Experimental Hit Rate

Instead of random fractionation and blind bioassays, brands receive a prioritized list of peptides predicted to interact with validated biochemical targets (e.g., DPP-IV, ACE, NF-κB). Higher confidence in candidate selection means fewer wasted assays and lower cost per lead.

3. Mechanistic Hypotheses for Marketing & Regulatory Dossiers

Docking results provide structural hypotheses of mechanism — which residues contact the active site, which pocket anchors binding, and what interactions drive affinity. Those mechanistic data are persuasive for R&D reports, regulatory submissions, and science-backed marketing.

Key Molecular Targets in Nutrition & Health Peptide R&D

Brands should focus docking efforts on targets with clear translational potential for functional food endpoints. Typical nutrition-related targets include:

- Metabolic health: DPP-IV, GLP-1 receptor interactions, AMPK modulation — relevant to blood glucose control and weight-supporting products.

- Cardiovascular & performance: ACE inhibition, antioxidant enzymes (SOD), and nitric oxide pathways — relevant to vascular health and sports nutrition.

- Inflammation & immunity: NF-κB, COX-2, and cytokine receptors — useful for gut & immune-support formulations.

- Gut-brain axis & neuromodulation: GABA receptors and monoamine-related enzymes — for sleep, stress, and cognition adjuncts.

Selecting high-quality structural models for these targets is a necessary first step before any peptide docking campaign.

Real-World Success Cases in Docking-Driven Peptide Innovation

Below are practical, public-facing case types where docking has demonstrably accelerated peptide ingredient development. These examples are descriptive — intended to illustrate workflows that brands can realistically engage in.

Case 1 — DPP-IV Inhibitory Peptides for Metabolic Support

Food-derived DPP-IV inhibitory peptides (from milk, soy, or plant proteins) have been identified through combined in silico screening and enzymatic hydrolysis workflows. Teams use docking to predict which di- and tri-peptides are likely to fit the DPP-IV active site, then validate top candidates in enzyme assays and cell models. The approach reduces discovery time and offers a pipeline for glycemic-support ingredient development (Liu et al., 2019).

Case 2 — ACE-Inhibitory Peptides for Vascular & Sport Health

Angiotensin-converting enzyme (ACE) inhibitors from dairy and marine hydrolysates are classic functional peptides. Docking helps to refine peptide sequences that optimally interact with ACE binding pockets; validated peptides then move into clinical-style blood pressure or exercise recovery studies. Successful commercial examples demonstrate how docking-informed selection supports regulatory dossiers and health claims.

Case 3 — Marine Peptides for Anti-Fatigue & Antioxidant Effects

Marine collagen and fish protein hydrolysates contain short peptides that interact with mitochondrial antioxidant pathways. Docking against antioxidant enzymes and mitochondrial targets helps prioritize sequences that enhance cellular resilience under physical stress — accelerating development of sports and anti-fatigue products.

Case 4 — Fermentation-Enhanced Peptides with Improved Bioactivity

Combining in silico docking predictions with targeted probiotic fermentation can enhance the yield and functionality of specific peptides. Docking predicts candidate sequences; fermentation processes then selectively release, concentrate, or modify these peptides to improve bioavailability and downstream functionality.

These case workflows are reproducible on an industrial scale when coupled with robust enzyme libraries, fermentation know-how, and manufacturing capacity.

PEPDOO® Platform — From Docking Predictions to GMP Production

AI + Molecular Docking Screening

We maintain target-focused virtual screening workflows that generate prioritized peptide candidates against nutrition-relevant receptors and enzymes. Docking outputs are combined with machine learning models to refine sequence scoring and predict ADME-like properties relevant to oral ingredients.

Proprietary Multi-Enzyme & Probiotic Fermentation Processes

PEPDOO®’s patented multi-enzyme hydrolysis and targeted probiotic fermentation amplify desired sequences while reducing off-target peptides and bitterness. This combination improves functional potency and sensory properties, aiding formulation and consumer acceptability.

Regulatory, Standards & Patent Strength

As a full-category peptide manufacturer and an active participant in China’s peptide standardization efforts, PEPDOO® holds a strong patent portfolio in small-molecule peptides and related production techniques. Our regulatory & quality systems (GMP, ISO, HACCP, export certifications) support global commercialization.

End-to-End Manufacturing & Commercialization

From raw-material sourcing and pilot-scale validation to full-batch production and private-label services (ODM/OEM), PEPDOO® bridges the gap between computational discovery and market-ready ingredients — reducing the handoffs that commonly slow product timelines.

SEO phrases to integrate on landing pages: peptide manufacturer, full-spectrum peptide supplier, peptide R&D partner China.

How Brands Can Operationalize Molecular Docking

If your product team is considering docking-driven peptide innovation, a practical engagement model looks like this:

- Define target & performance goal — e.g., DPP-IV inhibition for glycemic support, ACE inhibition for blood pressure benefits, antioxidant capacity for sports recovery.

- In silico library design — digestion simulation, de novo sequence generation, or targeted motif sampling.

- Docking & prioritization — rapid virtual screening (Vina, AutoDock), scoring, and selection of top candidates.

- Synthesis / targeted hydrolysis — produce top candidates via chemical synthesis or tuned enzymatic hydrolysis + fermentation.

- Wet-lab validation — enzyme assays, cell models, stability & simulated digestion, optionally pilot clinical studies.

- Scale & commercialize — formulation, stability testing, production at GMP scale, and regulatory/labeling support.

This pipeline reduces wasted lab resources and provides defensible scientific narratives for product claims — important for procurement and regulatory teams.

Practical Considerations & Limits of Docking for Peptide Ingredients

Molecular docking is powerful but not omnipotent. Important caveats for B2B decision-makers:

- Conformational complexity: Longer peptides have many rotatable bonds; docking accuracy decreases with length unless combined with enhanced sampling and molecular dynamics.

- Scoring limitations: Absolute binding energy predictions are approximate; docking is best for ranking rather than exact affinity prediction.

- Bioavailability & digestion: A strong docked pose doesn’t guarantee oral bioavailability; digestion stability, intestinal transport, and first-pass metabolism must be evaluated.

- Integration requirement: The highest value comes when docking is integrated with tailored enzymology, fermentation optimization, and robust validation pipelines.

Understanding these limits allows teams to set realistic milestones and avoid overpromising.

Docking Is a Strategic Accelerator for Functional Peptide Innovation

For functional nutrition brands, molecular docking transforms peptide discovery from a probabilistic hunt into a targeted, mechanism-driven pipeline. When implemented professionally — combining computational screening, patented enzymatic and fermentation processes, and GMP manufacturing — docking-guided R&D shortens timelines, lowers costs, and improves the scientific credibility of product claims.

PEPDOO® offers the combined capabilities brands need: computational peptide discovery, patented small-molecule peptide manufacturing, active leadership in China’s peptide standardization, and international-grade production capacity. Partnering with a full-category peptide manufacturer and R&D collaborator like PEPDOO® converts docking predictions into validated, scalable ingredients that meet regulatory and market requirements.

Ready to convert docking insights into commercial peptide ingredients? Contact PEPDOO® to request a docking-assisted peptide screening proposal, sample set, and R&D roadmap.

Accelerate Peptide Innovation With Molecular Docking + Advanced Manufacturing

Partner with PEPDOO® — a global full-category bioactive peptide manufacturer, China peptide category standard setter, and leader in small-molecule peptide patents and next-generation hydrolysis + fermentation technology. Explore molecular-docking-guided discovery, formulation support, pilot production, and large-scale manufacturing for functional food, nutraceuticals, and FSMP applications.

- Custom peptide screening & docking-guided R&D

- Exclusive peptide IP & formulation co-development

- GMP / ISO / HACCP / HALAL certified production

- Samples, pilot batches & commercial manufacturing

- Application support: metabolism, immunity, gut health, healthy aging & more

FAQ

Molecular docking shortens development cycles by predicting peptide–target interactions before wet-lab testing. This allows teams to quickly prioritize candidates for metabolic, gut-health, antioxidant, anti-inflammatory or immune-support applications—reducing cost, time and trial-and-error risk.

Docking predicts binding affinity and interaction sites, not whole-body outcomes. Best practice combines: (1) docking & scoring, (2) in-vitro enzymatic/cell validation, (3) in-vivo studies, and (4) human data when required. PEPDOO® integrates virtual screening with targeted hydrolysis, fermentation and wet-lab validation to bridge prediction and real-world performance.

Common targets include ACE, DPP-IV, GLP-1/AMPK pathways, lipase/PPAR (lipid metabolism), NF-κB/Nrf2 (inflammation & oxidative stress) and peptide transporters (PEPT1/PEPT2) for bioavailability optimization. Targets are selected based on intended product claims and regulatory boundaries.

PEPDOO® provides an end-to-end pipeline: computational design, patented multi-enzyme hydrolysis & probiotic fermentation, molecular weight fingerprint control, food-grade GMP production, and stability/solubility optimization—ensuring predicted candidates can be manufactured at commercial scale.

Yes. We provide custom docking campaigns, targeted hydrolysis or synthesis, pilot batches and formulation support for beverages, supplements, FSMP, and personalized nutrition. Options include proprietary sequences, exclusivity agreements, or joint IP arrangements.

Common deliverables: COA, MSDS, specification sheet, amino-acid profile, molecular weight distribution reports, production certificates (GMP/ISO/HACCP/HALAL), and supportive research references. We assist alignment with US FDA (DSHEA), EU, China FSS and other regional regulations.

Typical stages: target definition → virtual screening (feasibility report) → wet-lab validation → pilot batch (1–20 kg) → scale production. MOQs are flexible for innovation projects; commercial volumes are supported by PEPDOO®'s full manufacturing capacity.

References

- Korhonen, H., & Pihlanto, A. (2006). Bioactive peptides: Production and functionality. International Dairy Journal, 16(9), 945–960. doi:10.1016/j.idairyj.2006.03.012

- Liu, R., et al. (2019). Discovery of Food-Derived Dipeptidyl Peptidase IV (DPP-IV) Inhibitory Peptides: Methods and Applications. Nutrients, 11(5), Article 1023.

- Morris, G. M., Goodsell, D. S., Halliday, R. S., Huey, R., Hart, W. E., Belew, R. K., & Olson, A. J. (1998). Automated docking using a Lamarckian genetic algorithm and an empirical binding free energy function. Journal of Computational Chemistry, 19(14), 1639–1662.

- Trott, O., & Olson, A. J. (2010). AutoDock Vina: Improving the speed and accuracy of docking with a new scoring function, efficient optimization, and multithreading. Journal of Computational Chemistry, 31(2), 455–461.