Why real-time control matters in peptide manufacturing

Enzymatic hydrolysis is the backbone of modern functional peptide production: by selectively cleaving proteins into bioactive peptide fragments, manufacturers can produce ingredients with antioxidant, anti-inflammatory, metabolic or performance-supporting functions. Yet traditional batch hydrolysis is empirical and end-point driven — operators rely on fixed time/temperature recipes and post-run testing. The result is avoidable batch-to-batch variability, longer lead times, and uncertain bioactivity profiles for high-value B2B customers.

Real-time peptide monitoring, enabled through Process Analytical Technology (PAT), changes that paradigm. PAT tools enable online, nondestructive measurement of hydrolysis kinetics and product attributes (degree of hydrolysis, molecular weight distribution, peptide fingerprinting) and feed those measurements into automated control loops. For buyers and formulators in functional nutrition, practical outcomes are immediate: consistent bioactivity, predictable scale-up, shorter time-to-market, and traceable quality from factory to finished product. [1]

From traditional hydrolysis to smart manufacturing

Traditional hydrolysis workflows are often optimized empirically: select an enzyme (or enzyme blend), set pH and temperature, run for a fixed time, then quench and test. That approach can work for exploratory R&D but is a poor fit for industrial supply chains that demand reproducibility, regulatory compliance, and predictable functionality.

Key pain points for B2B customers include:

- Batch variability in peptide molecular-weight distributions that affect bioactivity and formulation performance.

- Reactive quality control (test after production) that increases scrap and rework.

- Limited traceability, complicating claims and regulatory dossiers for specialty nutrition channels.

Switching to PAT and real-time monitoring converts hydrolysis from an empirical art to a data-driven engineering discipline. PAT lets manufacturers monitor critical process parameters and critical quality attributes as they develop, then act on them — stabilizing output and enabling consistent specification adherence for downstream formulation and clinical testing. This is increasingly expected by functional-food and nutraceutical brands that purchase ingredients with performance guarantees. [1][2]

What is Process Analytical Technology (PAT)?

Process Analytical Technology (PAT) is a science- and risk-based framework that supports real-time measurement and control of manufacturing processes to ensure final product quality. Originally formalized for pharmaceuticals, PAT principles apply directly to peptide hydrolysis: define critical quality attributes (CQAs), identify suitable sensors and analytics, collect and analyze multivariate data, and implement feedback or feed-forward controls that keep CQAs in their target windows. [1]

For hydrolysis, relevant CQAs include degree of hydrolysis (DH), peptide molecular-weight distribution (MWD), presence of specific marker peptides, and impurity profiles. Critical process parameters (CPPs) include enzyme dose and activity, temperature, pH, substrate concentration, and mixing/shear. PAT ties CPP measurements to CQAs in real time so that production can be steered dynamically rather than corrected at the end of a run. [2]

2.1 Core Principles of PAT in Hydrolysis

- Real-time data acquisition

- Multivariate analysis

- Feedback control mechanisms

Core analytical tools for real-time peptide monitoring

A PAT strategy for hydrolysis typically layers multiple complementary analytical technologies. No single instrument solves every need; instead, a combination of spectroscopic sensors, rapid separations, and selective probes gives both speed and specificity.

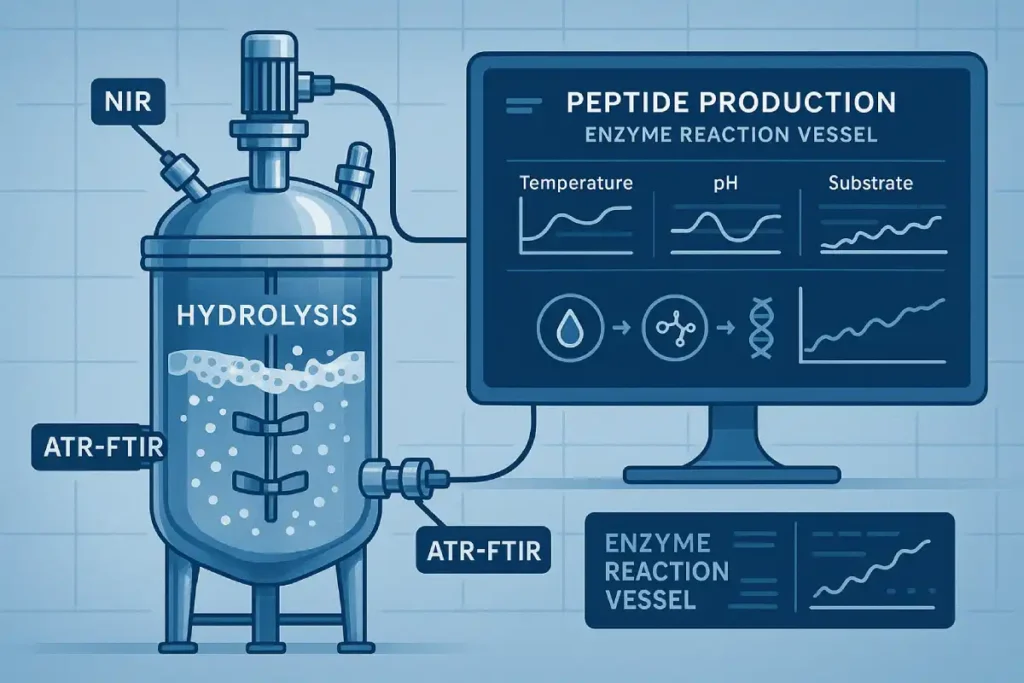

1. Spectroscopy (NIR / ATR-FTIR / UV–Vis / Raman)

Spectroscopic sensors excel at fast, nondestructive measurements and are widely used for estimating DH and compositional changes. Near-infrared (NIR) spectroscopy, for example, correlates spectral patterns with hydrolysis progression and can deliver second-scale updates to multivariate models used for prediction. ATR-FTIR and UV–Vis add orthogonal signals for backbone modification and peptide bond cleavage dynamics. These sensors are ideal for closed-loop control because they impose minimal sample handling. [3]

2. Fluorescence and selective probes

Fluorescent probes or intrinsic fluorescence measurement can sensitively track the exposure of aromatic residues during hydrolysis and provide a rapid proxy for specific cleavage events. Fluorescence sensors are especially useful when tracking peptides that contain characteristic fluorescent residues or tags added for process development.

3. Online chromatography / LC–MS integration

For high-resolution molecular-weight distribution and peptide fingerprinting, rapid chromatographic methods or online LC–MS are indispensable. Recent advances allow near-real-time LC workflows that quantify targeted peptide markers and offer direct evidence of bioactive sequences. While chromatographic methods have longer cycle times than spectroscopy, they validate and calibrate PAT models and are crucial for specification release and claim substantiation. [4]

4. Sensor fusion and multivariate data analysis (MVDA)

The power of PAT emerges when spectral, chromatographic, and process sensor signals are fused using MVDA (PCA, PLS, PLS-DA) and machine learning to produce robust, predictive models. Those models translate raw sensor readings into actionable quality estimates (e.g., predicted DH, fraction of <1 kDa peptides) that feed automated setpoint adjustments.

Data-driven quality control: closed-loop hydrolysis

A mature PAT implementation moves beyond monitoring to closed-loop control. In practice, real-time analytics predict a quality metric (e.g., “target peptide window achieved”) and trigger automated interventions: adjust enzyme feed, shift temperature, modulate pH, or shorten the reaction hold. These interventions minimize over-hydrolysis (loss of target functionality) and reduce off-spec product.

For B2B partners, this translates to:

- Consistent functional profiles (same MWD and marker-peptide content across batches).

- Faster scale-up with model-based predictability between pilot and production lines.

- Lower scrap and higher yield, improving cost certainty for OEM formulas.

Case studies in protein hydrolysis show that integrating NIR models with feedback control can quantify DH in real time and actively hold reactions at the “hydrolysis window” that optimizes target bioactivity. [5][6]

Benefits for functional peptide manufacturing and B2B customers

Implementing PAT and real-time monitoring yields measurable advantages for peptide suppliers and their downstream customers:

- Reproducible bioactivity and specification conformity

Brands buying peptides for functional foods or therapeutic nutrition need ingredients with predictable performance. PAT reduces variability and supports specification certificates that purchasing and R&D teams can trust. - Faster product development and predictable scale-up

Model-driven hydrolysis shortens the path from concept to commercial production by converting lab-scale kinetics into production setpoints with less trial-and-error. - Regulatory and compliance readiness

PAT frameworks align with global quality paradigms (QbD/PAT principles) and make regulatory audits more straightforward by documenting how CQAs are measured and controlled in real time. [1][2] - Cost and sustainability gains

Reduced over-processing, fewer failed batches, and optimized enzyme usage lower COGS and resource consumption — a strong sustainability argument for procurement teams.

PEPDOO®’s intelligent hydrolysis platform (example application)

As peptide manufacturers adopt PAT, leading factories combine hardware (sensors, automated dosing), software (MVDA, predictive analytics), and domain knowledge (enzyme selection, substrate pre-treatment). A fully integrated platform might include:

- Inline NIR and ATR-FTIR probes for fast DH estimation;

- Real-time pH, temperature, and dissolved oxygen monitoring;

- Automated enzyme dosing with PID or model predictive control (MPC);

- Periodic online LC-MS sampling to recalibrate models;

- Secure data capture and digital documentation for traceability.

When implemented by a full-category peptide manufacturer, this stack supports both standard catalog products (with tight specs) and custom OEM/ODM work where customers require specific peptide fingerprints or clinical-grade reproducibility.

For procurement and R&D teams, partnering with a supplier that deploys PAT means predictable lead times, validated specifications, and a technical pathway to scale tailored peptide formulations from pilot to production. [3][4]

Toward fully digitalized peptide factories: digital twins and Bioprocess 4.0

Looking ahead, PAT converges with Digital Twin technology and Bioprocess 4.0 strategies to create virtual models of hydrolysis lines. Digital twins run “what-if” experiments, test recipe changes without interrupting production, and accelerate troubleshooting. This enables adaptive operations — switching between different peptide product profiles on the same line with rapid model-driven reconfiguration. Business benefits include higher line utilization and faster response to new product requests from R&D or private-label customers. [7]

Digital twins and AI models also improve long-term process robustness: as more runs feed the model, predictive maintenance and continuous process optimization reduce downtime and increase throughput — a clear advantage for B2B supply agreements.

Practical considerations for procurement and R&D teams

When evaluating peptide suppliers or specifying production requirements, B2B buyers should look for clear evidence of PAT capability and its practical implications:

- Measurement strategy: Does the supplier use inline sensors (NIR/ATR-FTIR/UV) complemented by periodic chromatographic validation?

- Model validation: Are predictive models (e.g., PLS for DH) validated across raw material lots and scales?

- Control logic: Can the supplier demonstrate closed-loop control (enzyme dosing, temperature/pH adjustments) that reduces variance?

- Traceability & documentation: Are real-time data and calibration records available for audit and quality review?

- Customization capability: Can the supplier tune hydrolysis windows to enrich specific peptide fractions or marker peptides required for your formulation?

Demanding these capabilities protects brand reputation and eases reformulation if raw materials or regulations change.

Partner with a PAT-enabled peptide manufacturer

If your brand demands consistent functional performance and predictable supply, evaluate suppliers on their PAT footprint and data governance. A PAT-enabled manufacturing partner delivers reproducible peptide fractions, faster development cycles, and stronger evidence for label claims — all key to winning in competitive functional-nutrition markets.

Ready to upgrade your peptide supply chain? Contact a PAT-enabled peptide manufacturer to discuss specification development, pilot runs, and how real-time peptide monitoring can de-risk your product roadmap.

Enhance Your Peptide Production with Real-Time Precision

Partner with PEPDOO® — a global full-category peptide manufacturer and standard-setter in China’s functional peptide industry. Discover how real-time process analytical technology can elevate your R&D, scale-up, and market success.

Contact Our Technical TeamFAQ

Real-time peptide monitoring enables continuous tracking of peptide formation, enzyme activity, and molecular weight distribution during hydrolysis. This ensures optimal enzyme dosage, reaction time, and temperature control—reducing batch variability and enhancing yield consistency. For large-scale manufacturers, this translates into shorter development cycles and reduced waste.

Advanced Process Analytical Technology (PAT) tools such as near-infrared (NIR) spectroscopy, fluorescence sensing, and online chromatographic analysis are commonly used. These methods allow for dynamic, in-situ analysis of peptide concentration and bioactivity evolution during enzymatic hydrolysis.

Yes. Real-time monitoring systems are designed for compatibility with various hydrolysis reactors and can be customized according to substrate type (e.g., soy, collagen, oyster, rice) and enzyme systems. PEPDOO® engineers assist clients in system integration to ensure seamless data capture and quality control alignment with GMP standards.

For peptide suppliers, PAT provides robust process control and reproducibility, allowing for standardization across product batches. For functional food brands and nutraceutical developers, it ensures transparency, traceability, and quantifiable consistency in peptide quality—key factors for clinical validation and market differentiation.

As a full-category peptide manufacturer, PEPDOO® integrates multi-stage enzymatic hydrolysis with AI-assisted real-time monitoring systems. These systems measure reaction kinetics and peptide chain length distribution in real time, ensuring precise control of target bioactivities such as antioxidant, anti-inflammatory, and lipid metabolism modulation.

Common challenges include sensor calibration in complex food matrices, enzyme-specific signal interference, and data interpretation accuracy. However, advanced AI algorithms and machine learning models—such as those implemented by PEPDOO®—are overcoming these limitations by improving prediction accuracy and process automation.

Manufacturers adopting real-time PAT typically observe:

- 10–20% improvement in hydrolysis efficiency

- 30–40% reduction in batch inconsistency

- Faster product development through predictive process modeling

- Improved customer trust through traceable quality data

These benefits directly contribute to higher profit margins and faster time-to-market for functional peptide ingredients.

PEPDOO® offers joint development programs, pilot-scale validation, and OEM/ODM cooperation for brands seeking precision-controlled peptide ingredients. Our R&D support covers enzymatic system design, data-driven quality control, and scalability analysis—helping partners shorten innovation cycles and differentiate their functional nutrition products.

Absolutely. Scalable PAT platforms can be tailored for both pilot-scale and industrial-scale hydrolysis setups. PEPDOO® assists smaller manufacturers with modular solutions that allow gradual system upgrades as production capacity expands.

The next generation of PAT involves:

- AI-assisted spectral analysis for real-time decision-making

- Inline peptide fingerprinting for quality-by-design (QbD) assurance

- Cloud-based data integration enabling multi-site process control

PEPDOO® is actively investing in these directions to maintain global leadership in peptide manufacturing innovation.

References

- [1] U.S. Food and Drug Administration. (2004). Guidance for Industry: Process Analytical Technology — A Framework for Innovative Pharmaceutical Development, Manufacturing, and Quality Assurance. FDA.

- [2] Singh, A., & Lee, C. (2022). Applications of Process Analytical Technology in Bioprocessing. Biotechnology Advances, 60, 107988.

- [3] Hu, W., He, R., Hou, F., Ouyang, Q., & Chen, Q. (2016). Real-time monitoring of Alcalase hydrolysis using near infrared spectroscopy and modelling algorithms. Journal of Food Engineering.

- [4] Zhang, Y., et al. (2023). Advances in Online Monitoring of Enzymatic Hydrolysis for Peptide Production. Food Chemistry, 407, 135214.

- [5] Gerzon, G. (2022). Process Analytical Technologies — Advances in bioprocess integration and future perspectives. Biotechnology Reviews.

- [6] Hu, W., & Chen, Q. (2016). Real-Time Monitoring of Enzymatic Hydrolysis Using Near Infrared Spectroscopy. Journal of Food Engineering, 173, 45–53.

- [7] Zobel-Roos, S., et al. (2023). Digital twin based design and experimental validation for peptide process optimisation. Processes.