1. Precision Separation Reshaping Peptide Innovation

Peptide fractionation is redefining the frontier of functional ingredient innovation. By isolating specific bioactive sub-sequences from complex hydrolysates, manufacturers can design targeted nutritional peptides with proven physiological efficacy and stability. This approach allows functional food, dietary supplement, and medical nutrition brands to move from generic protein hydrolysates toward scientifically validated, performance-driven formulations.

As a comprehensive peptide manufacturer, PEPDOO® leads this transition through its integration of enzymatic hydrolysis, multi-stage fractionation, and bioinformatics-guided discovery. As a standard-setter in China’s peptide industry and one of the top enterprises in small-molecule peptide patents, PEPDOO® provides global partners with next-generation peptide ingredients backed by science and manufacturability.

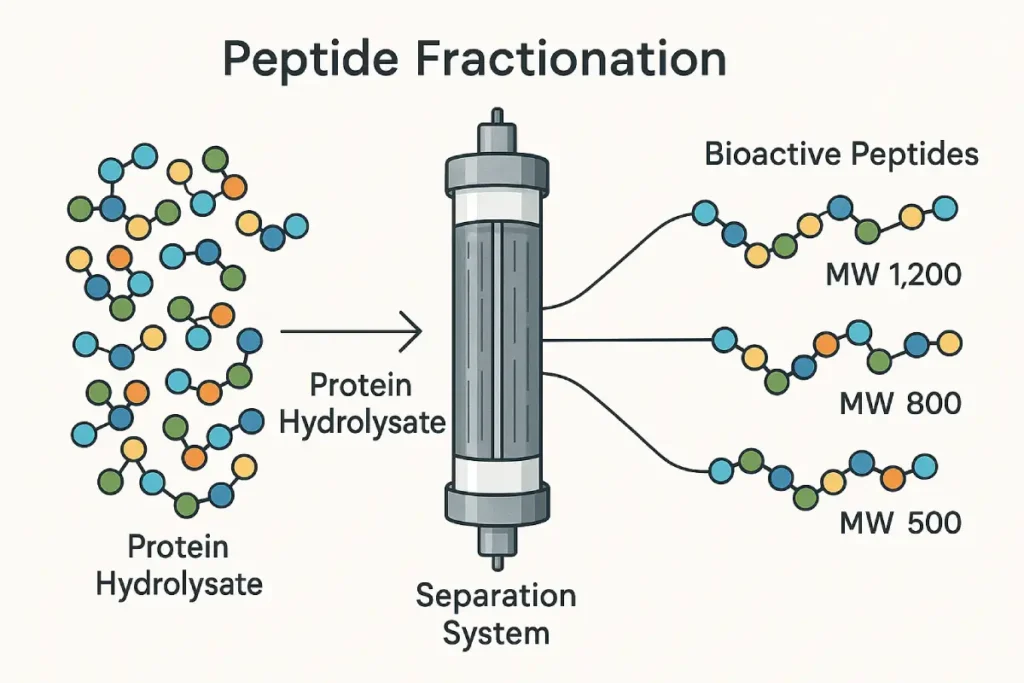

2. From Enzymatic Hydrolysates to Precision Peptide Fractions

Traditional enzymatic hydrolysis produces a heterogeneous mixture of peptides with varying molecular weights and random sequences. While these mixtures offer general nutritional benefits, their inconsistent activity and unclear functional attribution limit their clinical and formulation value [1].

In contrast, peptide fractionation enables selective separation of peptides based on molecular weight, charge, or polarity, revealing the specific sub-sequences responsible for biological activity. This precision parallels the shift from “general nutrition” to precision nutrition, where formulations are molecularly designed to support targeted outcomes — such as metabolic regulation, gut balance, or collagen synthesis.

PEPDOO®’s multi-enzyme hydrolysis and gradient fractionation platform achieves controllable molecular weight distributions (from <1 kDa to >10 kDa), enabling tailored functional applications for food, supplement, and clinical nutrition brands.

3. What Is Peptide Fractionation and Why It Matters

Peptide fractionation refers to the separation of peptide mixtures into fractions with distinct physicochemical and biological properties. The process enhances bioactivity, purity, and reproducibility, and forms the foundation of functional peptide research [2].

Key technologies include:

- Ultrafiltration (UF): Separates peptides by size using membranes with defined molecular weight cut-offs (MWCO).

- Ion-Exchange Chromatography (IEC): Differentiates peptides based on charge, isolating acidic or basic fractions.

- High-Performance Liquid Chromatography (HPLC): Purifies analytical-grade peptides with high precision.

Advanced characterization tools — such as LC-MS/MS and peptide fingerprinting — map the sequence and confirm the structural integrity of each peptide fraction, ensuring traceable and reproducible activity.

Within PEPDOO®’s GMP-certified manufacturing system, fractionation is integrated as a critical control step, ensuring consistent purity, bioactivity, and scalability for global peptide applications.

4. Unlocking Hidden Bioactive Sub-Sequences: The Molecular Frontier

Hidden within large protein hydrolysates are short-chain bioactive peptides (2–20 amino acids) that regulate crucial physiological pathways. Through fractionation, these functional motifs can be isolated, concentrated, and verified for activity.

Scientific research has identified diverse activities in these sub-sequences:

- ACE inhibition: supports healthy blood pressure [3]

- DPP-IV inhibition: enhances glucose metabolism and satiety [4]

- Collagen synthesis stimulation: promotes dermal and joint regeneration

- Antioxidant and anti-glycation activity: protects against cellular oxidative stress [5]

Case Study – Soy Peptide Fractionation

PEPDOO®’s study on 3–5 kDa soy peptide fractions demonstrated 2.8× higher antioxidant activity (DPPH assay) compared to crude hydrolysates, along with enhanced muscle endurance in animal models. This fraction was later incorporated into sports nutrition formulations aimed at fatigue recovery and antioxidant defense.

Case Study – Oyster Peptide Purification

Through marine peptide fractionation, PEPDOO® enriched taurine-linked tripeptides that showed a 45% increase in nitric oxide synthesis modulation, supporting male vitality and cardiovascular performance. These results demonstrate how targeted purification enhances both efficacy and product differentiation.

PEPDOO® continues to lead bioactive peptide discovery by linking functional fraction data with structure–activity correlation, offering B2B clients validated ingredient blueprints for functional innovation.

5. Commercial Applications Across Functional Nutrition Segments

Peptide fractionation technology enables the creation of high-performance peptide ingredients across key nutrition categories:

| Application Area | Fraction Example | Functional Benefit |

|---|---|---|

| Sports Nutrition | 1–3 kDa whey peptides | Rapid absorption, reduced muscle fatigue |

| Beauty-from-Within | Collagen tripeptides | Enhanced dermal collagen synthesis |

| Gut & Immune Health | Fermented rice peptide fractions | Microbiota modulation, improved gut barrier integrity |

| Metabolic Health | Pea and mulberry peptide fractions | Improved glucose control, anti-glycation properties |

As a global peptide manufacturer, PEPDOO® collaborates with functional food, nutraceutical, and TCM modernization brands to develop fraction-based functional ingredients. Each co-developed blend undergoes in vitro and in vivo validation, ensuring measurable performance for B2B clients.

This application diversity underscores the potential of fractionated peptides to replace traditional extracts and synthetic additives in modern formulations.

6. Industrial-Scale Peptide Fractionation: From Lab to Factory

Scaling peptide fractionation from research to industrial production requires advanced process control. PEPDOO®’s industrial-scale peptide fractionation system integrates enzymatic hydrolysis, multi-membrane filtration, HPLC, and low-temperature concentration into a seamless, automated workflow.

Key capabilities include:

- Precision molecular weight control via AI-assisted monitoring

- Batch-to-batch reproducibility validated by peptide fingerprinting

- Energy-efficient low-temperature concentration for bioactivity retention

- Compliance with GMP, HACCP, and ISO standards

Case Study – Rice Peptide for Infant Nutrition

PEPDOO® developed a hypoallergenic rice peptide fraction (<1 kDa) optimized for infant and clinical nutrition. The fraction showed excellent digestibility and amino acid balance while maintaining hypoallergenic properties — successfully applied in peptide-based enteral nutrition formulas in partnership with domestic and European brands.

This demonstrates PEPDOO®’s ability to translate R&D-grade peptide fractionation into commercial-scale production, aligning scientific innovation with industrial reliability.

7. Scientific Validation and Quality Assurance

Quality assurance in peptide manufacturing extends beyond purity; it involves proving biological efficacy and molecular reproducibility. PEPDOO®’s validation framework includes:

- LC-MS/MS sequence confirmation for structure identity

- In vitro activity verification (ACE, DPP-IV, antioxidant assays)

- In vivo physiological evaluation for efficacy and safety

- Solubility and stability profiling under formulation conditions

Each peptide fraction is characterized by a unique molecular fingerprint, ensuring traceability across batches.

By correlating molecular size, amino acid sequence, and biological function, PEPDOO® has established one of China’s most comprehensive peptide verification systems, setting benchmarks now referenced by multiple domestic industry standards.

8. Future Outlook: AI-Driven Peptide Discovery & Digital Fractionation

The future of peptide innovation lies in the convergence of AI, bioinformatics, and fractionation technology. Artificial intelligence can now predict functional motifs from protein databases, guiding enzymatic hydrolysis and purification strategies toward desired bioactivities [6].

PEPDOO® integrates:

- AI-assisted hydrolysis optimization to target functional motifs

- Bioinformatics-guided sequence mapping for activity prediction

- Fermentation–fractionation coupling for sustainable, low-carbon production

This digital ecosystem transforms traditional peptide R&D into data-driven precision engineering, accelerating the path from discovery to commercialization.

With a robust R&D infrastructure and patented enzymatic systems, PEPDOO® continues to pioneer intelligent peptide manufacturing, reinforcing its global position as a leader in functional nutrition innovation.

9. Peptide Fractionation: Transforming Science into High-Efficacy Functional Ingredients

Peptide fractionation represents a paradigm shift in functional nutrition — from bulk hydrolysates to molecularly defined, science-backed ingredients. By uncovering hidden bioactive sub-sequences, this technology bridges the gap between biochemistry and product performance, enabling clean-label, high-efficacy solutions for modern consumers.

With over a decade of expertise, PEPDOO® stands as:

- A full-category peptide manufacturer,

- A standard-setter in China’s peptide industry,

- A top-ranking enterprise in small-molecule peptide patents, and

- A leader in internationally advanced peptide manufacturing technologies.

Unlock the Potential of Fractionated Peptides for Your Products

Collaborate with PEPDOO®, a leading full-category peptide manufacturer and industry standard-setter in China, to access scientifically validated, high-efficacy functional peptide solutions for your brand.

Contact Our Technical TeamFAQ

Peptide fractionation involves separating complex peptide mixtures into specific molecular weight or sequence ranges using techniques such as ultrafiltration or chromatography. This enables the identification and concentration of sub-sequences with proven bioactivity—improving bioavailability, stability, and functional efficacy in nutraceutical applications.

It allows R&D teams to pinpoint bioactive peptides responsible for targeted physiological effects—such as anti-glycation, gut barrier enhancement, or immune modulation. Fractionation supports evidence-based formulation and helps differentiate new-generation functional foods with precise mechanism validation.

PEPDOO® integrates multi-enzyme hydrolysis, gradient membrane separation, and precision chromatography platforms. Our approach achieves superior purity and consistency in molecular size control. As a full-category peptide manufacturer and national standard-setter, we combine China’s leading small peptide patents with globally advanced manufacturing capabilities.

Peptides derived from soy, marine collagen, rice, oyster, or chicken sources can all be fractionated for enhanced functional performance. For instance, smaller fractions (below 1 kDa) typically exhibit higher absorption efficiency and stronger antioxidant or anti-inflammatory activity.

Yes. For example, hydrolyzed collagen tripeptides in beauty-from-within products and low-molecular-weight soy peptides for metabolic regulation are both results of targeted fractionation. PEPDOO® has supported multiple brands in developing clinically validated formulations for gut health and men’s vitality supplements using fractionated oyster and rice peptides.

Fractionated peptides deliver higher efficacy per dose, improve formulation stability, and enhance absorption. This enables B2B brands to justify premium pricing, accelerate clinical substantiation, and gain stronger competitive positioning in global functional nutrition markets.

PEPDOO®’s large-scale membrane fractionation and chromatography systems are fully scalable—from pilot R&D batches to ton-level industrial production. Each step is controlled under GMP and ISO-certified quality systems to ensure consistent peptide characteristics batch-to-batch.

Absolutely. PEPDOO® offers custom peptide blend development where bioactivity screening and fractionation are tailored to specific application goals—such as liver protection, blood sugar regulation, or skin elasticity. This flexibility supports brand differentiation and claim substantiation.

Our production facilities adhere to both Chinese national peptide standards (drafted by PEPDOO®) and international food-grade peptide regulations. We provide detailed technical dossiers and analytical data to support global registration and export documentation requirements.

PEPDOO® offers comprehensive B2B collaboration models including OEM/ODM production, custom peptide fraction development, and scientific co-research projects. As a global peptide innovation manufacturer, we welcome partnerships focused on functional nutrition, clinical formulations, and next-generation bioactive ingredient development.

References

1. Korhonen, H., & Pihlanto, A. (2006). Bioactive peptides: Production and functionality. International Dairy Journal, 16(9), 945–960.

2. Hayes, M., & Mora, L. (2018). Protein Hydrolysates and Bioactive Peptides in Food: Applications and Opportunities. Food Research International, 107, 93–101.

3. Vermeirssen, V., Van Camp, J., & Verstraete, W. (2004). Bioavailability of angiotensin I converting enzyme inhibitory peptides. British Journal of Nutrition, 92(3), 357–366.

4. Nongonierma, A. B., & FitzGerald, R. J. (2015). Dipeptidyl peptidase IV inhibitory peptides and their potential as functional food ingredients. Protein and Peptide Letters, 22(2), 149–158.

5. Sarmadi, B. H., & Ismail, A. (2010). Antioxidative peptides from food proteins: A review. Peptides, 31(10), 1949–1956.

6. Duda, K., & Zieliński, D. (2022). Machine learning in peptide bioactivity prediction: A comprehensive review. Computational and Structural Biotechnology Journal, 20, 5520–5537.