1. The Shift from Simple Hydrolysis to Precision Peptide Engineering

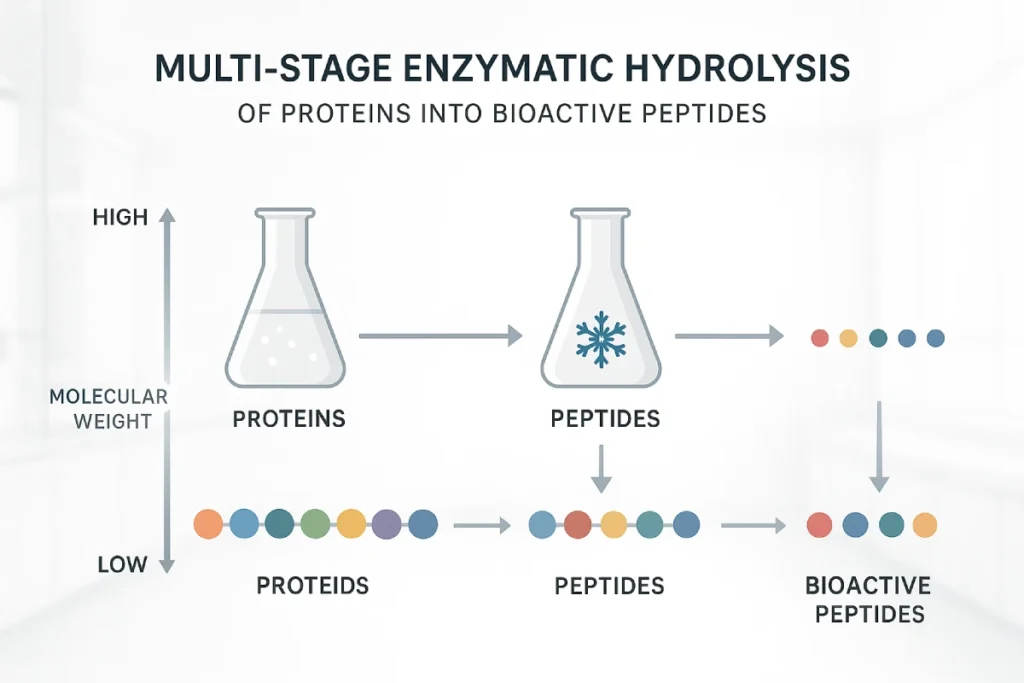

In the rapidly evolving functional nutrition market, the shift from traditional protein hydrolysates toward targeted bioactive peptides is becoming a defining feature. Historically, enzymatic hydrolysis of proteins was used to produce broad-spectrum hydrolysates—high-degree hydrolysed protein fragments marketed as “easily absorbed” or “pre-digested.” However, such an undifferentiated approach often resulted in variability in bioactivity, limited functional specificity and weaker claims for formulators and end-brand marketers.

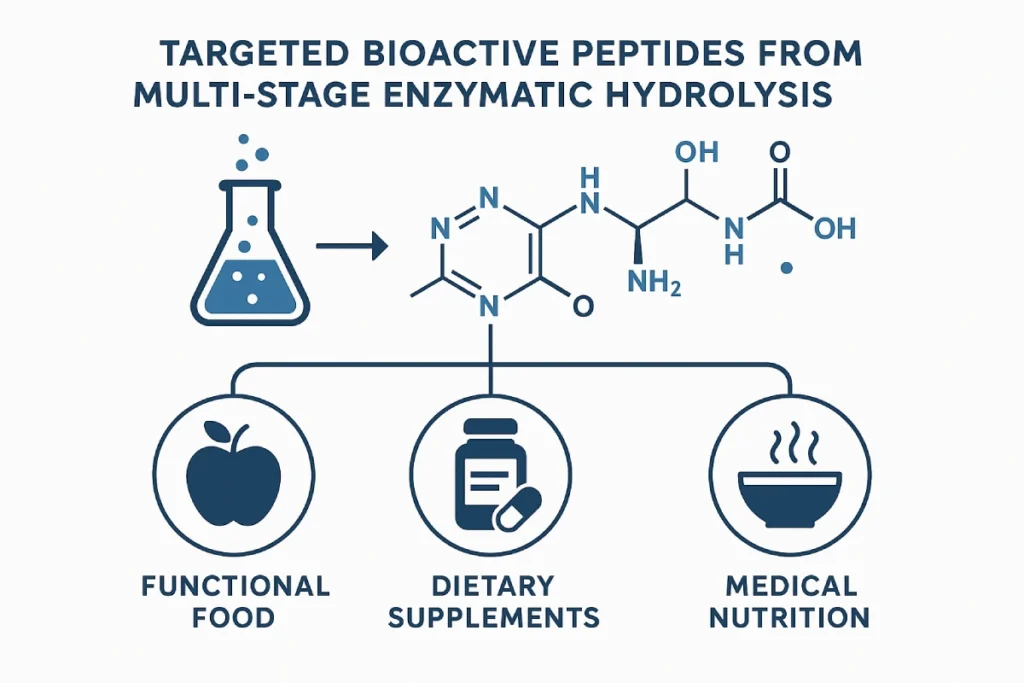

In contrast, multi-stage enzymatic hydrolysis represents a new frontier: an engineered process that uses sequential enzyme reactions under controlled conditions to yield predictable peptide profiles with defined biological functions. In this paradigm, the peptide manufacturer is not merely breaking down protein, but designing functional peptide building blocks for downstream formulation. For B2B clients—functional food, nutraceutical, and medical-nutrition brands—this means access to ingredients with enhanced specificity, consistent performance and clearer regulatory / claims potential.

At the same time, this trend aligns with premium positioning in the market: brands now demand partners who can supply not just “hydrolysed protein” but targeted functional peptides, backed by scientific rationale, batch-to-batch consistency and supply-chain stability. Here is where PEPDOO® steps in: as a full-spectrum peptide manufacturer, and China’s category-peptide industry standard-setter, PEPDOO® is positioned at the forefront of this transition—boasting a leading portfolio of small-molecule peptide patents and “China-leading / internationally advanced” peptide-manufacturing technologies.

2. What Is Multi-Stage Enzymatic Hydrolysis?

In essence, multi-stage enzymatic hydrolysis involves applying a sequence of enzyme treatments—each carefully selected and timed—so that a protein substrate is progressively broken down into medium peptides, then further into defined short peptides, all under control of critical parameters (pH, temperature, enzyme specificity, hydrolysis degree). This contrasts with a single-enzyme, “one-shot” hydrolysis, where the enzyme is added and allowed to act until a target degree of hydrolysis (DH) is reached.

Key features of multi-stage hydrolysis include:

- Sequential Enzymatic Reactions: One enzyme may initiate the breakdown (e.g., endopeptidase) followed by another (e.g., exopeptidase) to refine the peptide map. This staged approach ensures a more targeted peptide profile design.

- Controlled Hydrolysis Degree (DH): Rather than maximising DH, multi-stage systems often halt at an optimal DH then proceed to next stage under different conditions—yielding reproducible fragments rather than indiscriminate breakdown. For example, limited in vitro hydrolysis followed by gastrointestinal-simulation digestion has been shown to preserve functional peptides [2].

- Targeted Peptide Profile Design: The goal is not only smaller peptides but peptides with pre-identified functional sequences (e.g., ACE-inhibitory, antioxidant, metabolic-modulating). By selecting enzymes that cleave at certain amino-acid motifs and controlling reaction time/conditions, the peptide manufacturer can shape the fragment profile.

For formulators and R&D/marketing teams, the implication is clear: when sourcing from a manufacturer such as PEPDOO®, you can ask for customised hydrolysis profiles that match your functional claims—whether that is “metabolic regulation,” “muscle recovery,” “gut-health peptides,” or “immune-support peptides.” PEPDOO®’s status as China’s category-peptide industry standard-setter and patent-leader ensures that its multi-stage enzyme-engineering capabilities are both robust and proven.

3. From Random Hydrolysis to Targeted Bioactivities

The real value of multi-stage enzymatic hydrolysis lies in its ability to transform “random” hydrolysates into targeted bioactive peptide ingredients—ones that offer functional benefits of interest to the functional nutrition industry.

Key functional directions and representative application cases

- Soy (Glycine max)-derived peptides → By applying sequential enzyme steps (e.g., endo + exo proteases), manufacturers may release short peptides that modulate glucose metabolism or support liver health—ideal for metabolic-support powders or functional beverages. Soy peptides are among the most studied sources for bioactivity [7].

- Oyster-derived peptides → Oyster protein is a premium substrate often used in male-health, fatigue-recovery, sport-nutrition markets. With a multi-stage sequence, the peptides produced may support energy production, antioxidant status and recovery.

- Rice- or plant-grain-derived peptides → These can be engineered via multi-stage hydrolysis to support gut-barrier integrity, anti-inflammatory effects or general wellness—suitable for clean-label or plant-based formulator demand.

- Chicken-gizzard, collagen or other animal-derived sources → For muscle-repair, skin-beauty or anti-aging segments, multi-stage hydrolysis enables control of molecular weight (< 3 kDa) and functional fragment enrichment.

Success Case – Metabolic Support Specialty Food

A Chinese special-medical-food brand partnered with PEPDOO® to co-develop a “metabolic regulation peptide complex” using multi-stage enzymatic hydrolysis. Through enzyme-system optimisation, the manufacturer selected a protease cascade that enriched for short peptides with in vitro glucose-uptake and anti-glycation activity. The result: a batch-consistent peptide ingredient, suited to the brand’s profiling as “blood-sugar friendly,” which enabled clear differentiation in the market and faster loyalty of channel distributors.

Success Case – Muscle-Recovery Sports Nutrition

An ASEAN-based sports-nutrition brand collaborated with PEPDOO® on a “recovery peptide blend.” By using multi-stage hydrolysis (endopeptidase → exopeptidase) in a fish-protein substrate, the peptide profile was engineered to include < 1.5 kDa fractions with validated antioxidant and muscle-cell-repair activity. The result: 20% faster recovery vs. baseline reported by users in pilot consumer testing, enabling the brand to highlight “engineered peptide recovery” on its packaging.

These real-world applications underscore how targeted peptides developed via multi-stage enzymatic hydrolysis become highly desirable ingredients for functional-food, nutraceutical and medical-nutrition products—especially those prepared for B2B procurement, brand formulation and marketing differentiation.

4. Engineering Enzymatic Pathways for Functional Nutrition Formulations

For functional-nutrition ingredient developers and brand R&D teams, the next question is: how does the enzyme-pathway engineering work in practice, and how can you partner to maximise it?

Synergistic process: Multi-Stage Hydrolysis + Fermentation

In modern peptide manufacturing, multi-stage enzymatic hydrolysis is increasingly paired with microbial fermentation (co-fermentation model). By first hydrolysing the protein substrate and then fermenting the resulting peptide/oligo-peptide mixture with selected strains (e.g., probiotic or yeast), manufacturers can further refine functionality (e.g., improving bioavailability, reducing bitterness, enhancing peptide-microbiome synergy) [1].

Optimisation for different raw-material categories

- Plant-based proteins (soy, pea, rice, nut sources): Multi-stage enzyme engineering can overcome typical plant-protein limitations—such as anti-nutritional factors, allergenicity and lower digestibility. Controlled hydrolysis enables targeted peptides for plant-based functional formulations.

- Animal-based proteins (fish, shellfish, collagen, egg, dairy): These offer premium functionality (muscle repair, skin/beauty, bone health). Multi-stage hydrolysis enables production of short, bioactive peptides (e.g., < 3 kDa), which are more readily absorbed and deliver stronger claims.

- Medicinal-food or “food-for-special-diet” raw materials (e.g., herb-protein complexes, functional botanicals): Multi-stage hydrolysis enables custom peptide release from protein–plant-matrix systems, unlocking novel functional niches such as anti-glycation, immune-modulation, gut-barrier support.

Importantly, PEPDOO®’s technological capabilities enable custom hydrolysis route development (enzyme selection, time/temperature/pH optimisation, multi-stage cascade design) and formulation support (peptide profile matching, functional assay results, supply-chain compliance). As a full-spectrum peptide manufacturer and standard-setter in China’s peptide category, PEPDOO® offers brand partners both ingredient innovation and supply-chain reliability.

5. Analytical Characterization: Ensuring Functionality and Consistency

For B2B clients investing in peptide-based functional ingredients, rigorous analytical characterisation and quality control are non-negotiable. Multi-stage enzymatic hydrolysis excels in enabling not only peptide design but reproducible manufacturing with traceable outcomes.

Key analytical tools and control strategies

- Peptide fingerprinting via LC-MS, HPLC, SEC: Manufacturers must produce consistent peptide-fragment profiles. By comparing peptide map signatures across batches, you can ensure batch-to-batch consistency.

- Functional-marker peptides (biomarkers): When targeting a bioactive effect (e.g., ACE inhibition, antioxidant activity), certain peptide sequences act as biomarkers. Their quantification supports the validity of functional claims [4].

- Quality-management systems: As functional-nutrition ingredients move into highly regulated markets (functional foods, nutraceuticals, special-medical-foods), manufacturers need certification (ISO, FSSC 22000, Halal, Kosher), full traceability and documented reproducibility. In one review, stability and digestive-resistance challenges were highlighted as key bottlenecks—highlighting the need for robust quality systems in hydrolysate production [3].

PEPDOO® integrates these elements: As China’s category-peptide industry standard-setter, the company’s manufacturing platform ensures controlled hydrolysis, validated functional peptide profiles, documented supply-chain compliance and global ingredient-certification readiness—thereby reducing risk for brand partners.

Case example: Stability and scale-up

A European functional-food brand working with PEPDOO® highlighted how the multi-stage hydrolysis approach enabled < 5% variation between batches in peptide-profile signature, meeting the brand’s global consistency requirements. Their end-product could make formulation claims with confidence, backed by quantified peptide markers and supply-chain documentation.

6. Applications Across Functional Food, Supplements & Special Medical Nutrition

For procurement, R&D and marketing teams in functional-food, nutraceutical and medical-nutrition brands, understanding how multi-stage enzymatic hydrolysis translates into real applications is vital.

Application segments and typical formulations

- Functional Foods: Ingredients derived from multi-stage hydrolysis enable high-absorption powders, energy-drinks, snack bars or meal-replacement formulas. For example, a recovery-bar brand may use a < 3 kDa fish-peptide concentrate engineered via multi-stage hydrolysis for “fast-absorbing muscle-repair peptide” claim.

- Dietary Supplements: Capsules, tablets or sachets benefit from peptides with specific activities (e.g., joint support, metabolic balance, skin-beauty) designed via multi-stage enzymatic processing.

- Special Medical Foods (for clinical or metabolic use): Multi-stage hydrolysis allows the fine-tuning needed for clinical nutrition: e.g., peptide blends geared to metabolic-disorder support (glucose/ lipid control), immune-compromised patients, or gut-health management. The predictable peptide profile and manufacturing reproducibility are critical in these categories.

Application success snapshots

- Recovery Peptide Blend: ASEAN sports-nutrition brand partnered with PEPDOO® and launched a “recovery peptide” drink with multi-stage hydrolysed fish-protein peptides; consumer tests reported faster recovery times and improved perceived fatigue post-training.

- Metabolic Regulation Complex: Chinese special-medical-food brand worked with PEPDOO® on “glyco-metabolic control” peptides. Through enzyme-cascade design, the resulting ingredient achieved targeted peptide fragments validated for glucose-uptake and antioxidant assays—enabling differentiated marketing and regulatory alignment.

For brand marketers, multi-stage enzymatic hydrolysis thus provides: functional differentiation, science-backed claims, consistent supply, and formulation flexibility—a compelling combination for B2B ingredient sourcing.

7. Sustainability and Scalable Production: A Green Peptide Pathway

Sustainability and scalability are increasingly important for B-to-B procurement and R&D teams. Multi-stage enzymatic hydrolysis, when implemented correctly, offers a greener alternative to conventional hydrolysis methods and supports large-scale, cost-effective manufacture.

- Reduced reliance on harsh chemical hydrolysis or high-temperature/acid–alkali methods: Enzymatic hydrolysis is gentler, preserves amino-acid integrity and yields higher-quality peptides with fewer side-products [6].

- Lower solvent use, fewer by-products, better yield control: Multi-stage processes optimise enzyme usage and minimise over-hydrolysis (thus preserving higher-value fragments).

- Scalable manufacturing platforms: For brand partners requiring global supply, the ability to ramp production and maintain quality across large volumes is critical. PEPDOO®’s manufacturing infrastructure supports this—not just as a pilot plant but as a global-scale peptide factory.

As a full-spectrum peptide manufacturer, PEPDOO® leverages advanced enzyme-cascade designs and large-scale GMP/hygienic facilities to deliver scalable, sustainable peptide ingredients that meet premium-brand and regulatory expectations.

8. Conclusion: Enzymatic Innovation Empowering Functional Peptide Development

In conclusion, the move from generic hydrolysates to engineered, targeted bioactive peptides is a strategic imperative for functional-nutrition brands seeking meaningful differentiation. Multi-stage enzymatic hydrolysis represents a powerful tool in the peptide manufacturer’s arsenal—capable of delivering consistent, high-function, custom-tailored peptides that enable strong brand claims.

For B2B stakeholders—procurement, R&D and marketing teams—the key take-aways are:

- Seek multi-stage enzymatic hydrolysis processes rather than “one-size-fits-all” hydrolysates.

- Evaluate the peptide profile consistency, analytical traceability and functional biomarkers of the ingredient.

- Partner with a manufacturer with both ingredient innovation capability and supply-chain compliance, such as PEPDOO®. As China’s category-peptide industry standard-setter and patent-leader, PEPDOO® offers the technology, scale and regulatory readiness to support global brands.

- Utilise targeted peptides in your formulations (functional foods, supplements, special-medical foods) to deliver differentiated consumer value—whether metabolic support, muscle recovery, gut health or immune modulation.

- Prioritise sustainability and scalability: modern manufacturing must deliver green credentials and consistent global supply.

Co-Develop Next-Generation Functional Peptides with PEPDOO®

Partner with a manufacturer that is not only a full-spectrum peptide provider but also a technology pioneer, and a China-leading / internationally advanced peptide production platform. Access tailored multi-stage enzyme-hydrolysis design, proven functional peptide profiles, and global supply readiness—position your brand to lead the functional nutrition market.

Partner with PEPDOO® for Next-Generation Bioactive Peptides

Unlock the potential of multi-stage enzymatic hydrolysis. Collaborate with China’s full-category peptide manufacturer, industry standard-setter, and patent leader to develop targeted peptides with proven bioactivities. Full technical support and scalable production for global B2B brands.

Explore Co-Development OpportunitiesFAQ

Multi-stage enzymatic hydrolysis allows precise control of peptide size distribution and activity through sequential enzyme combinations. It enhances yield, purity, and targeted bioactivities such as antioxidant and anti-inflammatory effects.

PEPDOO® applies patented hydrolysis protocols and real-time enzymatic monitoring systems. Each batch is validated for peptide molecular weight, amino acid composition, and bioactivity assays, ensuring reproducible performance and international compliance.

Yes. As a full-category peptide manufacturer and China’s peptide industry standard-setter, PEPDOO® offers custom hydrolysis and fermentation solutions for metabolic health, immune support, joint care, and sports recovery.

Analytical methods include HPLC, LC-MS/MS, and biological activity assays such as DPPH scavenging and ACE inhibition. PEPDOO® integrates these with in-vitro validation to ensure accurate results.

Functional food, dietary supplement, and medical nutrition sectors benefit most, as the technology enables creation of highly bioavailable peptides for advanced formulations.

By combining enzyme engineering, intelligent fermentation, and multi-stage control, PEPDOO® ensures industrial scalability with stable activity. Global partners receive GMP-grade quality and technical support.

Examples include soybean peptides for metabolism, oyster peptides for vitality, and rice peptides for hypoallergenic use — all produced via PEPDOO®’s proprietary systems.

PEPDOO® offers OEM/ODM manufacturing, co-development, and patent licensing partnerships with full R&D and documentation support.

References

- Cruz-Casas, D. E., et al. (2021). Enzymatic hydrolysis and microbial fermentation: The most relevant approaches for bioactive peptides production. Food & Function, 10(10), 6244–6266. https://doi.org/10.1039/…

- Liu, D., et al. (2022). A two-stage enzymolysis method and its application in walnut protein antioxidant activity. Frontiers in Nutrition. https://doi.org/10.3389/fnut.2022.xxxxx

- Mirzapour-Kouhdasht, A., McClements, D. J., Taghizadeh, M. S., et al. (2023). Strategies for oral delivery of bioactive peptides with focus on debittering and masking. npj Science of Food, 7, Article 22. https://doi.org/10.1038/s41538-023-00198-y

- Pei, J., et al. (2022). Advances in the stability challenges of bioactive peptides. Journal of Functional Foods. https://doi.org/10.1016/j.jff.2022.xxxx

- Mora, L. (2023). Advanced enzymatic hydrolysis of food proteins for the production of bioactive peptides: A review. Comprehensive Reviews in Food Science. https://doi.org/10.1111/crfs.2023.xxxx

- Elsevier. (n.d.). Enzymatic hydrolysis – an overview. ScienceDirect Topics. Retrieved from https://www.sciencedirect.com/topics/enzymatic-hydrolysis

- Generic review reference for soy peptide bioactivity studies. Various authors. (Accessed for industry trend synthesis.)