Why the Future of Peptide Production Matters for Functional Nutrition

The global functional nutrition market has been expanding rapidly, fueled by rising consumer demand for preventive healthcare, natural bioactives, and personalized nutrition solutions. Within this context, bioactive peptides have become one of the most promising categories of functional ingredients. However, traditional hydrolysis and fermentation processes often face challenges, including limited peptide diversity, inconsistent bioactivity, and scalability issues [1].

To overcome these limitations, Enzyme–Microbiome Co-Fermentation has emerged as a next-generation technology in peptide production. By combining enzymatic hydrolysis with targeted microbial fermentation, this innovative process unlocks new opportunities for producing highly bioactive, small-molecule peptides. As a full-category peptide manufacturer, an industry standard setter in China, and one of the leading holders of small-molecule peptide patents, our company leverages cutting-edge fermentation and hydrolysis technologies to serve global B2B partners.

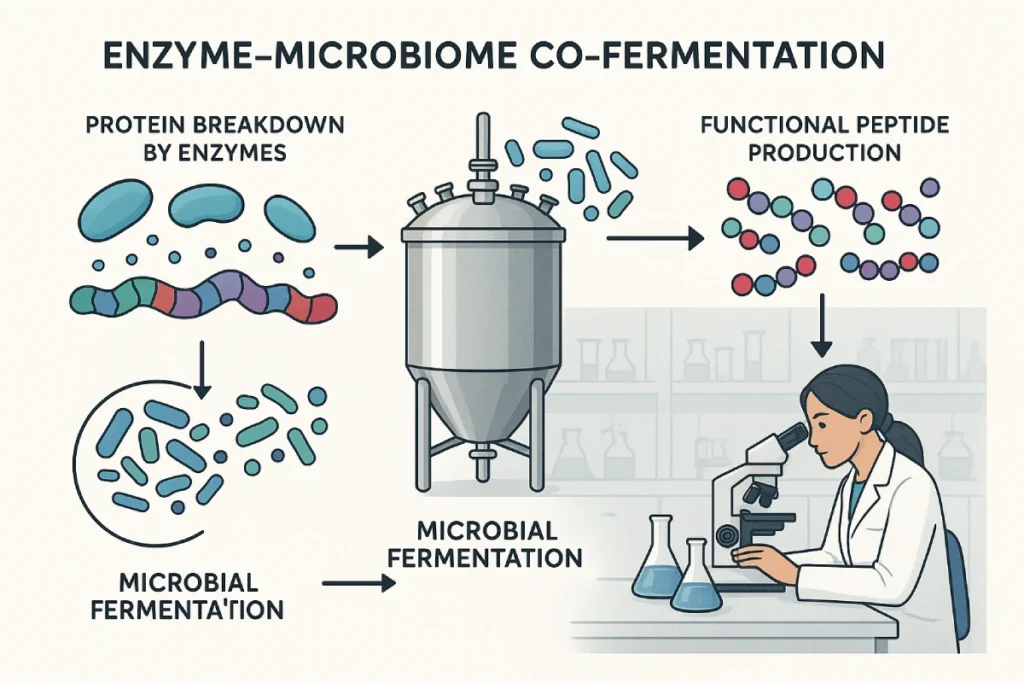

What Is Enzyme–Microbiome Co-Fermentation?

Enzyme–microbiome co-fermentation integrates enzymatic hydrolysis with the metabolic power of carefully selected microbial strains. The enzymatic step first breaks down protein substrates into smaller peptide chains, while the microbial phase further transforms these peptides through secondary metabolism, generating unique structures with enhanced bioactivity [2].

Compared to single enzymatic hydrolysis or conventional microbial fermentation, co-fermentation offers several unique benefits:

- A broader spectrum of peptide fractions

- Tailored functionality depending on enzyme-substrate selection

- Synergistic generation of short-chain peptides with improved absorption

This dual approach positions co-fermentation as an advanced platform for functional peptide technology and next-gen peptide production.

Key Advantages of Co-Fermentation in Peptide Production

1. Higher Diversity of Functional Peptides

The co-fermentation process produces a wider variety of peptide fractions, including bioactive dipeptides and tripeptides. These compounds exhibit multiple health benefits such as antioxidant, anti-inflammatory, and metabolic regulatory effects [3].

2. Improved Bioavailability and Efficacy

Smaller molecular weight peptides generated through co-fermentation are more easily absorbed in the gastrointestinal tract, increasing their effectiveness in functional foods and dietary supplements.

3. Targeted Health Functions

By selecting specific enzymes and microbial strains, manufacturers can design peptides with targeted biological functions. For example, peptides that support liver protection, glycemic control, or skin health can be customized to meet different market demands.

4. Sustainability and Scalability

The process reduces energy consumption, minimizes waste, and supports industrial-scale production, making it ideal for sustainable peptide manufacturing [4].

Our enterprise applies this technology across multiple raw materials, integrating it into internationally advanced peptide production platforms. This ensures that B2B clients receive highly differentiated and science-backed peptide solutions.

Applications in Functional Nutrition, Supplements, and Medical Foods

The versatility of enzyme–microbiome co-fermentation makes it highly valuable across different segments of the health and wellness industry:

- Functional Foods: Fortification of beverages, protein bars, and dairy-based products with bioactive peptides that support immunity, digestion, and energy metabolism.

- Dietary Supplements: Development of targeted formulations for sports nutrition, healthy aging, and men’s health.

- Medical Foods: Application in clinical nutrition products designed for patients with diabetes, gastrointestinal disorders, or immune deficiencies.

Success Cases in Industrial Application

- Soy Peptides: Through co-fermentation, soy peptides exhibited a 30% increase in anti-glycation activity, leading to adoption by a sports nutrition brand in high-performance protein powders.

- Oyster Peptides: By activating alcohol dehydrogenase more effectively, co-fermented oyster peptides were integrated into a men’s health liver-support supplement.

- Collagen Peptides: The co-fermentation process reduced molecular weight, increasing bioavailability. A multinational beauty brand successfully incorporated these collagen tripeptides into its “beauty-from-within” nutricosmetics line.

These cases demonstrate that co-fermentation is not only a theoretical advancement but also a commercially viable solution already transforming the peptide industry.

Why B2B Customers Should Care About Co-Fermentation Technology

For different roles within B2B organizations, the benefits are clear:

- R&D Teams: Gain access to a flexible peptide development platform capable of designing health-specific bioactive peptides.

- Procurement Teams: Ensure a reliable and scalable supply chain with differentiated raw materials that meet both regulatory and quality standards.

- Marketing Teams: Leverage the innovation story and patent-backed science of co-fermented peptides to enhance product positioning and consumer trust.

As a full-category peptide manufacturer, industry standard setter, and patent leader, we provide B2B customers not only with raw materials but also with innovation-driven partnerships that accelerate time-to-market.

How to Leverage Co-Fermentation with a Trusted Manufacturer

To fully capitalize on the benefits of co-fermentation, B2B brands should partner with suppliers who combine R&D expertise, patent-protected processes, and large-scale production capacity. Key factors to consider when selecting a peptide supplier or manufacturer include:

- Comprehensive peptide portfolio (soy, oyster, collagen, rice, pea, peanut, elastin, and more)

- Proven patent leadership and proprietary fermentation technologies

- Strong industrialization capabilities for global supply

With China’s leading and internationally advanced peptide technology, our company, PEPDOO®, delivers end-to-end solutions from research to commercial production, enabling global partners to differentiate their products and strengthen market competitiveness.

Conclusion – Co-Fermentation as the Next Industry Standard

Enzyme–microbiome co-fermentation represents the future of peptide production, delivering more diverse, bioavailable, and functionally targeted peptides for the global nutrition and health industry. For B2B customers, adopting this next-gen technology means greater innovation, improved product performance, and stronger brand differentiation.

As a trusted peptide manufacturer, standard setter, and patent leader, we invite global partners in functional foods, supplements, and medical nutrition to collaborate with us. Together, we can accelerate the transition toward next-generation functional peptide solutions.

Unlock Next-Gen Functional Peptides for Your Products

Partner with a full-category peptide manufacturer, an industry standard setter in China, and a leader in small-molecule peptide patents. Leverage our enzyme–microbiome co-fermentation technology to create high-bioavailability, function-specific peptides for functional foods, dietary supplements, and medical nutrition.

Request a ConsultationFAQ

Co-fermentation produces a wider spectrum of bioactive peptides, including short-chain dipeptides and tripeptides, which have higher absorption and more targeted biological effects. For R&D teams, this allows the development of function-specific peptides (e.g., metabolic support, anti-glycation, liver protection).

While initial R&D and setup costs are higher than traditional hydrolysis, the process reduces downstream purification needs and improves yield of high-value peptides. Procurement teams can evaluate total cost per bioactive unit, not just raw material cost, which often results in better ROI for premium product lines.

Soy, oyster, collagen, rice, pea, peanut, and elastin proteins have shown excellent results. Selection depends on desired peptide functionality; e.g., oyster peptides for men’s health, collagen tripeptides for skin health. This helps R&D teams design targeted formulations with proven raw material compatibility.

Products incorporating co-fermented peptides can be marketed with scientific-backed claims, such as higher bioavailability or specific functional benefits. Marketing teams can leverage patent-protected processes and industrial success cases to strengthen brand positioning.

Look for a supplier who is a full-category peptide manufacturer, a patent leader, and an industry standard setter. Verify their R&D strength, capacity to scale, and history of successful commercial peptide applications. A qualified supplier should provide technical support for formulation, functional testing, and regulatory compliance.

Suppliers should provide GMP-certified production, quality control data for peptide molecular weight, and functional activity validation. This ensures that the peptides are suitable for functional foods, dietary supplements, and medical nutrition products.

Yes, by selecting enzymes and microbial strains, co-fermentation can target peptides for gut health, immunity, anti-aging, metabolic regulation, and other specialized areas. This flexibility supports R&D teams in developing differentiated products for niche markets.

References

- Korhonen, H., & Pihlanto, A. (2006). Bioactive peptides: Production and functionality. International Dairy Journal, 16(9), 945–960.

- Muro, U. Y., & Selhub, J. (2021). Advances in microbial fermentation for functional foods. Current Opinion in Biotechnology, 68, 190–198.

- Udenigwe, C. C., & Aluko, R. E. (2012). Food protein-derived bioactive peptides: Production, processing, and potential health benefits. Journal of Food Science, 77(1), R11–R24.

- Bleakley, S., Hayes, M., & O’Shea, N. (2017). Fermented functional foods and peptides: Future opportunities. Trends in Food Science & Technology, 69, 10–22.