Why Collagen Peptides Matter in Functional Nutrition

Collagen peptides have emerged as a cornerstone ingredient in the functional nutrition and nutraceutical industries. From dietary supplements and functional foods to medical nutrition products, these bioactive peptides are increasingly recognized for their role in supporting skin health, joint integrity, and overall wellness [1]. For B2B customers such as R&D specialists, procurement managers, and brand developers, understanding the production efficiency, purity, and functional activity of collagen peptides is critical for product innovation and market differentiation.

At PEPDOO®, we are more than a raw material supplier. We are a full-category peptide manufacturer, a Chinese industry standard setter for peptide products, and a leading patent holder in small-molecule peptides. Leveraging cutting-edge international peptide synthesis technologies, we provide B2B clients with high-purity collagen peptides tailored for specific functional applications.

Understanding Collagen Peptides

Collagen peptides are short-chain amino acids derived from hydrolyzed collagen, typically sourced from bovine bone, fish skin, or poultry connective tissues. They are classified based on molecular weight, with low-molecular-weight peptides exhibiting superior bioavailability and enhanced functional efficacy [2].

Functional benefits include:

- Skin health: Stimulating collagen synthesis to improve elasticity and hydration.

- Joint support: Enhancing cartilage regeneration and reducing joint discomfort.

- Sports nutrition: Supporting muscle recovery and connective tissue integrity.

For B2B clients, the molecular weight, purity, and functional activity are crucial parameters for developing innovative formulations that differentiate products in a competitive market.

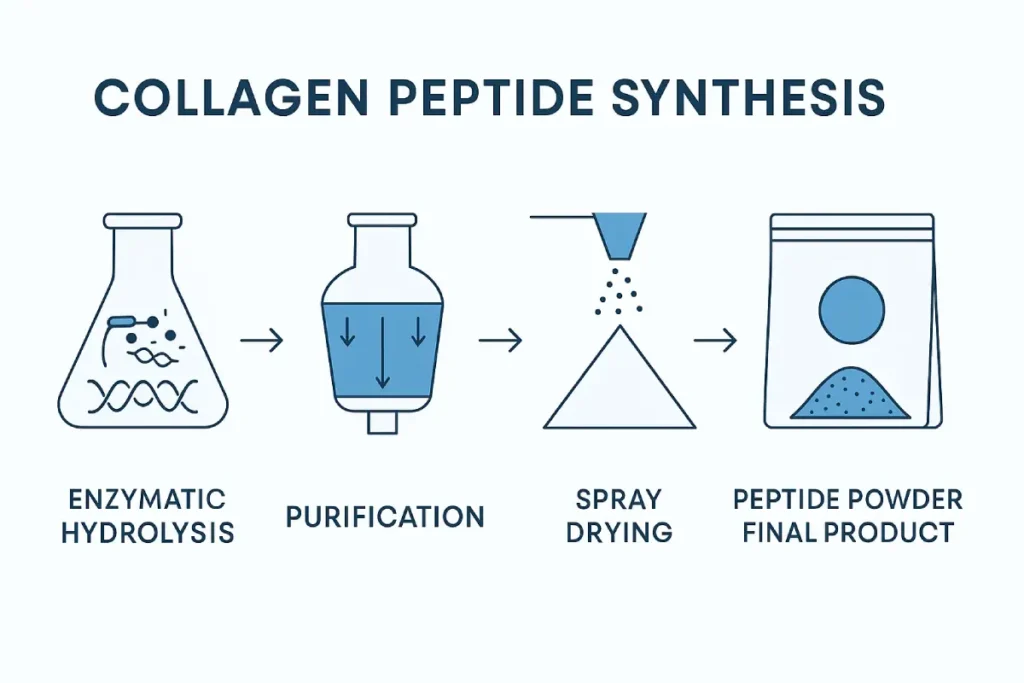

Traditional vs. Modern Synthesis Methods

Traditional collagen peptide production methods, such as acid or alkaline hydrolysis, provide basic hydrolyzed collagen but often compromise peptide functionality and generate inconsistent molecular weight distributions. Enzymatic hydrolysis emerged as a more refined approach, enabling precise control over peptide chain length and activity.

Recent advancements include:

- Optimized enzyme combinations that maximize yield and bioactivity.

- Controlled hydrolysis conditions for reproducible molecular weight profiles.

- Fermentation-assisted synthesis to enhance functional properties and reduce production time [1].

Modern methods not only increase production efficiency but also ensure the high purity and functional integrity necessary for high-end nutraceutical and functional food applications.

Maximizing Efficiency in Collagen Peptide Production

Efficiency is a major concern for B2B customers seeking scalable, cost-effective peptide solutions. Key strategies include:

- Raw Material Selection and Pre-treatment: Selecting high-quality collagen sources—bovine bone, fish skin, or poultry connective tissue—and optimizing pre-treatment steps ensures higher hydrolysis efficiency.

- Optimized Enzymatic Hydrolysis and Fermentation: Tailored enzyme blends and controlled fermentation parameters increase yield while maintaining peptide bioactivity.

- Continuous Production and Scale-up: Implementing continuous reactors and large-scale fermentation systems reduces batch variability and production costs.

Ensuring Purity and Functional Integrity

High purity and preserved bioactivity are critical for premium functional nutrition applications. Techniques to ensure these qualities include:

- Molecular Weight Fractionation: Ultrafiltration and chromatographic methods separate low-molecular-weight peptides for superior absorption.

- Functional Activity Preservation: Controlled hydrolysis ensures bioactive peptides retain antioxidative, anti-glycation, and collagen-stimulating effects.

- Compliance and Safety: GMP-certified processes, ISO standards, and food-grade certifications guarantee product reliability for B2B applications [2].

Enterprise Advantage: As a full-category peptide manufacturer and industry standard setter, PEPDOO® ensures that every batch meets stringent purity and bioactivity requirements.

Applications in Functional Nutrition & B2B Opportunities

Collagen peptides are increasingly integrated into:

- Functional foods: Drinks, bars, and fortified snacks.

- Dietary supplements: Capsules, powders, and effervescent tablets.

- Medical nutrition products: Targeted formulations for skin, joint, and muscle health.

B2B customers should evaluate suppliers based on production capacity, patent portfolio, customization capabilities, and technological leadership.

Future Trends in Collagen Peptide Synthesis

Looking ahead, the industry is moving toward:

- Next-generation low-molecular-weight collagen peptides with enhanced bioavailability.

- Sustainable and green peptide production using alternative raw materials and eco-friendly processes.

- Intelligent manufacturing with real-time monitoring and process automation, ensuring consistent quality and efficiency [1][2].

Partner with a Leading Collagen Peptide Manufacturer

Collagen peptide production today requires a combination of efficiency, purity, and functional consistency. PEPDOO® offers B2B clients unparalleled expertise as a full-category peptide manufacturer, industry standard setter, and leading patent holder in small-molecule peptides, using state-of-the-art international peptide synthesis technologies.

Partner with a Leading Collagen Peptide Manufacturer

At PEPDOO®, we are not only a full-category peptide manufacturer but also a patent leader and industry standard setter in China. With advanced international peptide technology, we deliver high-purity collagen peptide solutions for global B2B brands.

Get in TouchFAQ

For B2B clients in the functional foods, nutraceuticals, and FSMP sectors, advanced collagen peptide synthesis ensures consistent quality, high purity, and better bioavailability. This translates into products with stronger clinical credibility and greater consumer acceptance, helping brands differentiate in competitive markets.

As a full-category peptide manufacturer and industry standard setter, PEPDOO® provides flexible OEM/ODM services. We offer tailored hydrolysis processes, patented fermentation methods, and adjustable peptide molecular weights to meet specific application requirements in beverages, capsules, powders, and functional snacks.

Numerous studies have demonstrated the benefits of collagen peptides on skin elasticity, joint health, and metabolic balance [1][2]. At PEPDOO®, we actively collaborate with universities and research institutions to validate the efficacy of our peptides through human and pre-clinical trials, ensuring reliable outcomes for B2B clients.

Our production facilities are certified with ISO, HACCP, GMP, and meet global export standards. With China’s leading and internationally advanced peptide technologies, we support partners in passing regional regulatory reviews such as FDA, EFSA, and CFDA. This helps shorten time-to-market for functional nutrition brands.

Our peptides have been successfully applied in anti-aging supplements launched in Japan, joint support formulations in Europe, and high-protein beauty drinks in Southeast Asia. These cases highlight collagen peptides as versatile, clinically backed ingredients that generate strong consumer demand and business growth for brand partners.

PEPDOO® is not just a supplier—we are a global innovation partner. With one of the highest numbers of small-molecule peptide patents in China, we combine source manufacturing strength, advanced enzymatic hydrolysis, and scalable production capacity. For B2B clients, this means competitive pricing, reliable supply chain security, and cutting-edge product differentiation.

References

[1] Bello, A. E., & Oesser, S. (2006). Collagen hydrolysate for the treatment of osteoarthritis and other joint disorders: a review of the literature. Current Medical Research and Opinion, 22(11), 2221–2232.

[2] Zdzieblik, D., Oesser, S., Gollhofer, A., & König, D. (2015). Improvement of functional ankle properties following collagen peptide supplementation in athletes: a randomized controlled trial. Journal of the International Society of Sports Nutrition, 12(1), 3.