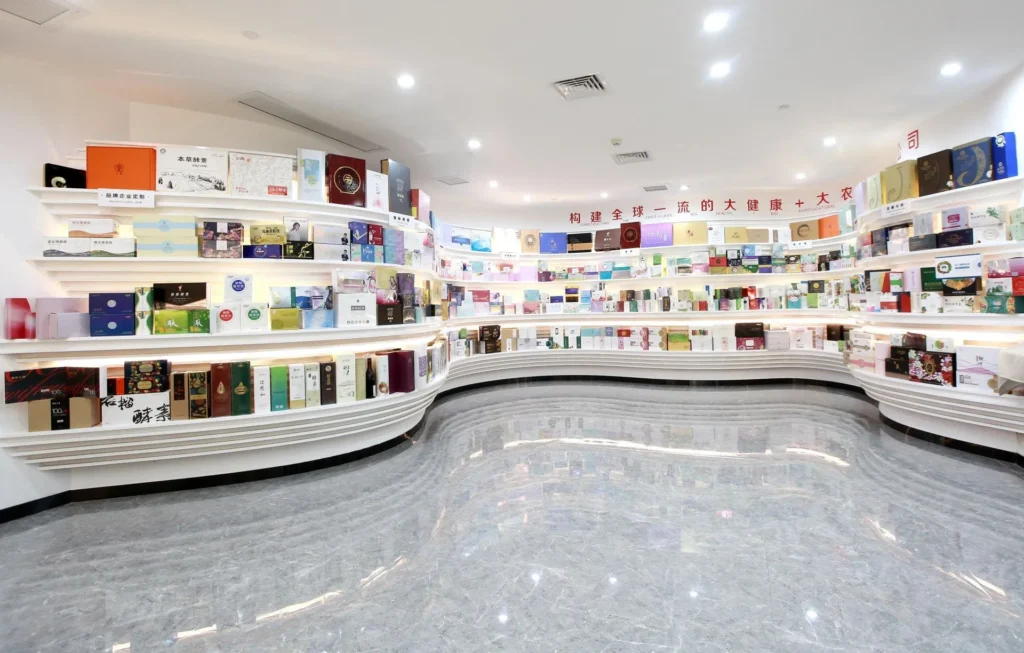

In an era of global health consciousness, dietary supplements have moved from niche alternatives to mainstream essentials. At the heart of this expansive industry lies a pivotal player: the health supplement manufacturer. Today’s leading manufacturers have transcended their traditional role as mere contract producers. They are integrated solution providers, combining cutting-edge science, rigorous quality control, regulatory intelligence, and market insight to serve as the foundational partner behind successful brands.

The Evolution: From Executor to Strategic Partner

The historical role was limited to production-on-order. Modern manufacturers, however, must operate on multiple fronts:

The R&D and Innovation Engine: With in-house teams of biologists, nutritionists, and food scientists, they conduct raw material research, formulation design (e.g., synergizing probiotics with specific peptides for enhanced bioavailability), and dosage-form innovation (e.g., developing stable, palatable collagen gummies), translating frontier science into consumable products.

The Guardian of Regulatory Compliance: Navigating complex global frameworks—from the U.S. FDA’s DSHEA and EU’s EFSA health claim regulations to China’s filing system—requires deep expertise. Manufacturers must ensure end-to-end compliance in sourcing, labeling, and documentation, shielding brand owners from significant legal and reputational risk.

The Stabilizer of Supply Chains: From sourcing certified organic botanicals to high-purity marine collagen peptides, manufacturers build resilient, audited global supply networks to guarantee raw material quality and availability, buffering against market volatility.

Core Competencies: Building the Unassailable Moat

The excellence of a supplement manufacturer is measured by tangible benchmarks:

Certifications & Facilities: cGMP (current Good Manufacturing Practice) certification is the baseline, not the ceiling. FDA-registered facilities, ISO 22000 (food safety management), NSF (for sports nutrition), or USDA Organic processing certifications are testaments to their quality commitment. 100,000-class cleanrooms and automated production lines are the physical infrastructure ensuring purity and preventing cross-contamination.

Science and Data-Driven Approach: This goes beyond having a lab. It means providing third-party Certificates of Analysis (CoA) for ingredients, conducting stability studies to validate shelf life, and supporting structure/function claims with clinical evidence. For instance, a sleep aid product should be backed by scientific literature or data demonstrating the efficacy of its core ingredient (e.g., casein peptide) in reducing sleep latency.

Flexibility and Scalability: The market demands serving two key client types: startups needing low Minimum Order Quantities (MOQ) and rapid prototyping, and established brands requiring high-volume production efficiency and complex logistics. Manufacturers must adeptly offer a full spectrum from Private Label (stock formulas) to full Custom Formulation (ODM).

Market Challenges and the Manufacturer’s Response

The industry faces multifaceted challenges: rising consumer demand for “clean label” (simple, natural ingredients); e-commerce requirements for compact, durable, and photogenic packaging; and the amplification of any quality issue via social media.

Forward-thinking manufacturers are responding by:

Investing in “clean” formulation technologies, seeking effective natural preservatives and flow agents.

Establishing dedicated packaging innovation units to design sustainable, consumer-friendly DTC (Direct-to-Consumer) packaging.

Embracing digital transformation, utilizing technologies like blockchain for end-to-end traceability from raw material to finished bottle, building trust through transparency.

The Future: Convergence of Precision Nutrition and Personalized Manufacturing

The future is imminent. With the proliferation of genetic testing and health monitoring devices, the “one-size-fits-all” model will gradually give way to personalized nutrition. This presents the ultimate challenge for manufacturers: can they leverage flexible production technologies to create small-batch, customized formulations for niche groups or even individuals? Those investing in micro-dosing, rapid line changeovers, and data analytics today will define the industry’s next decade.

Conclusion

Therefore, selecting a health supplement manufacturer is fundamentally choosing a strategic ally that will shape a brand’s destiny. It is a decision rooted in trust, expertise, and shared growth. Beyond price and lead time, brands must deeply evaluate a manufacturer’s scientific prowess, quality culture, and agility in adapting to change. In the enduring race for health and wellness, the most lasting victories are built upon the most solid foundations. The world-class manufacturer is the essential engineer of that foundation.