The Rising Value of Collagen Peptides

Collagen peptides have emerged as one of the most dynamic raw materials in the functional nutrition industry, powering innovation in functional foods, dietary supplements, and medical nutrition. Their benefits range from supporting skin elasticity and joint health to aiding muscle recovery and elderly nutrition. As global demand rises, the ability to control hydrolysis and extraction technology has become a key differentiator for brands seeking to develop high-value products.

As a full-category peptide manufacturer, we not only provide a broad portfolio of collagen, marine, plant, and animal peptides but also stand as a China peptide industry standard setter, ranking among the top in small-molecule peptide patents. With China-leading and internationally advanced hydrolysis technologies, we empower global B2B partners to develop premium, differentiated products in an increasingly competitive market.

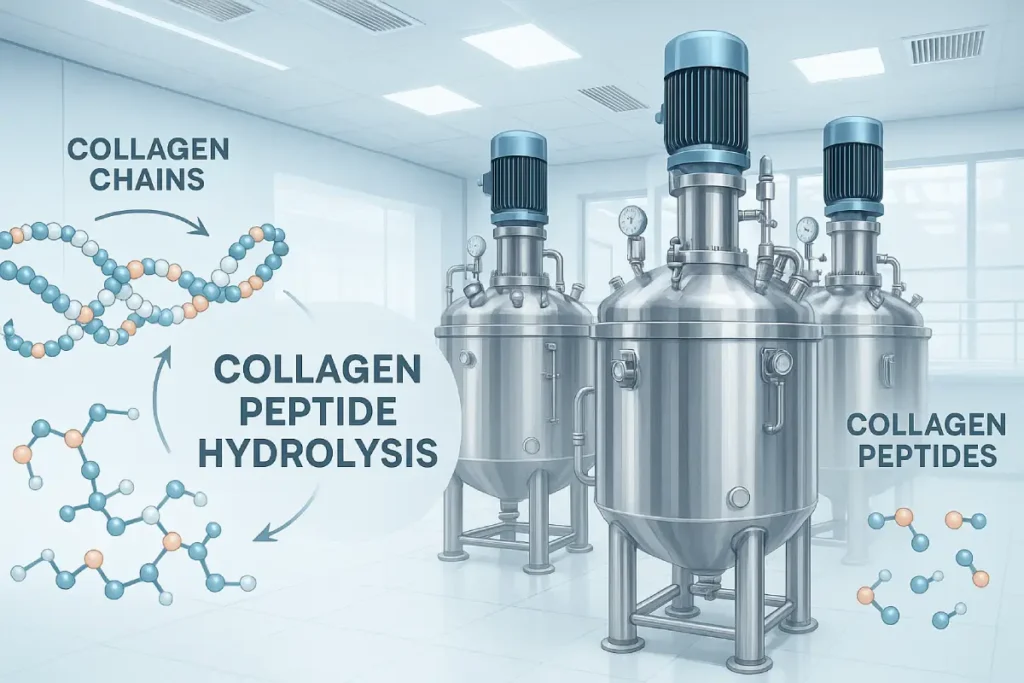

The Science of Hydrolysis: Why It Matters

Hydrolysis is the foundation of collagen peptide production. It refers to breaking down collagen macromolecules into smaller peptides, typically by enzymatic hydrolysis, which yields bioactive peptides with enhanced solubility and bioavailability [1].

- Molecular Weight & Bioavailability: Smaller peptides (below 1,000 Da) are absorbed more efficiently, offering faster and more consistent functionality.

- Sensory Properties: Hydrolysis directly influences solubility, transparency, and taste, which are critical for product formulations in beverages and powders.

- Comparative Approaches: Traditional acid/alkaline hydrolysis is being replaced by precision enzymatic extraction, which produces higher purity peptides while meeting clean-label demands.

For functional food developers, understanding the link between hydrolysis degree and product performance is essential when selecting a collagen peptide supplier.

What’s New in Collagen Peptide Extraction Technology?

Multi-Enzyme Synergistic Hydrolysis

Unlike single-enzyme methods, multi-enzyme hydrolysis uses a combination of proteases to produce a higher proportion of bioactive small-molecule peptides. This improves absorption rates and enhances biological functions such as antioxidation and anti-inflammation.

- Case Study: Our patented multi-enzyme hydrolysis technology helped a sports nutrition brand increase absorption efficiency by over 30%, resulting in a collagen peptide protein bar that became a top seller within three months.

Fermentation-Assisted Hydrolysis

Recent innovations combine probiotic fermentation (e.g., Lactobacillus plantarum) with hydrolysis to enhance peptide profiles and introduce additional bioactivities, such as gut health benefits.

- Case Study: In collaboration with a medical nutrition company, we developed a fermented collagen peptide powder designed for patients with sensitive digestive systems. The product achieved clean-label certification and successfully entered the hospital nutrition channel.

Membrane Separation and Ultrafiltration

Precise control over peptide size is achieved through membrane filtration technologies. This ensures batch-to-batch consistency and eliminates impurities, making peptides more suitable for clinical and premium formulations.

- Case Study: A beauty supplement brand used our ultrafiltration-grade collagen peptides to produce a clear, soluble collagen drink, boosting market acceptance in Asia’s beauty-from-within category.

Emerging Green Technologies

To meet sustainability demands, manufacturers are adopting high-pressure processing, ultrasound-assisted hydrolysis, and microwave-assisted extraction. These methods reduce energy use, enhance efficiency, and align with clean-label trends.

- Case Study: A European nutraceutical company partnered with us to utilize green hydrolysis processes, ensuring compliance with EU clean-label regulations and gaining an advantage in the eco-conscious consumer market.

The Value of Advanced Hydrolysis for B2B Brands

1. Quality Control

Advanced hydrolysis ensures precise molecular weight distribution, delivering consistent efficacy for end products.

2. Formulation Compatibility

Modern peptides are neutral in taste, highly soluble, and transparent, making them ideal for diverse applications such as ready-to-drink beverages, powders, and capsules.

3. Clinical Efficacy

Small-molecule collagen peptides demonstrate superior absorption and bioactivity, supporting strong scientific claims in beauty, joint, and medical nutrition categories [2].

4. Competitive Differentiation

By sourcing from a peptide manufacturer that is also an industry standard setter and patent leader, brands can leverage technical and regulatory credibility as a unique market positioning tool.

Market Applications: From Sports Nutrition to Medical Foods

- Sports Nutrition: Collagen peptides are widely used for muscle recovery and joint protection. A sports drink formulated with our collagen peptides helped an international brand penetrate Asia’s booming fitness market.

- Beauty Nutrition: With proven effects on skin hydration and elasticity, collagen peptides are central to nutricosmetic innovations. A collagen-hyaluronic acid drink developed with our peptides gained shelf space in Japanese beauty retail chains.

- Medical Nutrition: Collagen peptides are used in oncology recovery, elderly nutrition, and clinical nutrition powders. For example, our hydrolyzed collagen peptides have been included in formulations supplied to top-tier hospitals in China.

- Blended Formulations: Collagen peptides are increasingly combined with soy, oyster, and rice peptides to provide comprehensive metabolic, immune, and beauty benefits. Such cross-functional blends are gaining traction in premium formulations worldwide.

Choosing the Right Collagen Peptide Supplier: Key Factors for B2B Procurement

- Technical Capabilities – Availability of multi-enzyme hydrolysis, fermentation-assisted processes, membrane separation, and green extraction technologies.

- Industry Authority – Partnering with a China peptide industry standard setter and patent leader ensures compliance and credibility.

- Quality and Safety – Certifications such as GMP, ISO, FSSC22000, HALAL, and KOSHER guarantee global market readiness.

- R&D Collaboration – Access to OEM/ODM peptide solutions, custom formulations, and application support.

- Sustainability and Scale – Large-scale smart manufacturing facilities with raw material traceability ensure stable global supply.

By aligning with a collagen peptide manufacturer that embodies these qualities, brands can minimize risks and accelerate market success.

Conclusion: Driving Innovation in Functional Nutrition

Collagen peptide hydrolysis is entering a new era, where patented enzymatic processes, fermentation integration, membrane purification, and green technologies are setting higher standards for the industry.

For B2B stakeholders in functional foods, nutraceuticals, and medical nutrition, choosing a partner that is both a full-category peptide manufacturer and a China peptide industry standard setter provides unmatched advantages. With a patent-leading position in small-molecule peptides and internationally advanced hydrolysis technologies, we help brands capture growth opportunities with differentiated, clinically validated, and market-ready products.

Unlock the Potential of Collagen Peptides for Your Next-Generation Products

Partner with a full-category peptide manufacturer and China’s industry standard setter. Access patented small-molecule peptide solutions, OEM/ODM support, and advanced hydrolysis technologies to accelerate your B2B product innovation.

Request a Technical ConsultationFAQ

Advanced hydrolysis ensures smaller molecular weight peptides with higher bioavailability, neutral taste, and improved solubility. This helps functional food brands develop products that are not only effective but also consumer-friendly in taste and texture.

Partnering with a full-category peptide manufacturer like PEPDOO® means you gain access to diversified raw materials (soy, rice, fish, oyster, collagen, peanut, pea, etc.), patented hydrolysis technologies, and end-to-end customization (bulk supply, OEM/ODM). This reduces R&D risks and accelerates product launch timelines.

Yes. Using different hydrolysis methods and enzymatic processes, collagen peptides can be optimized for skin health (low molecular tripeptides for beauty), sports nutrition (high bioavailability for muscle recovery), or joint health (bioactive peptides for cartilage support).

Key aspects include compliance with FDA, EFSA, and China NHC standards, ensuring GRAS (Generally Recognized as Safe) status, and adhering to country-specific functional food regulations. Working with an industry standard setter ensures smoother registration and international approvals.

Collagen peptides are widely used in ready-to-drink beauty beverages in Asia, joint-care supplements in Europe, and sports powders in North America. These cases prove the scalability of collagen peptides in global functional nutrition markets.

China’s leading small-molecule peptide patents allow for unique formulations that competitors cannot easily replicate. This enables B2B partners to market differentiated products with stronger efficacy claims and higher brand value.

Beyond bulk peptide supply, we provide R&D support, application testing, formulation guidance, and regulatory documentation. This one-stop solution is designed to help your team move from concept to market efficiently.

References

- Proksch, E., Schunck, M., Zague, V., Segger, D., Degwert, J., & Oesser, S. (2014). Oral intake of specific bioactive collagen peptides reduces skin wrinkles and increases dermal matrix synthesis. Skin Pharmacology and Physiology, 27(3), 113–119.

- Clark, K. L., Sebastianelli, W., Flechsenhar, K. R., Aukermann, D. F., Meza, F., Millard, R. L., & Deitch, J. R. (2008). 24-Week study on the use of collagen hydrolysate as a dietary supplement in athletes with activity-related joint pain. Current Medical Research and Opinion, 24(5), 1485–1496.

- Zague, V. (2008). A new view concerning the effects of collagen hydrolysate intake on skin properties. Archives of Dermatological Research, 300(9), 479–483.