Tailoring Enzymatic Strategies for High-Performance Peptide Ingredients

In the fast-evolving world of functional nutrition, bioactive peptides are no longer niche components—they are foundational ingredients in health-oriented formulations. From sports recovery and metabolic health to immune support and anti-aging, peptides derived from natural protein sources are gaining global recognition. Yet, behind every successful peptide product lies a critical, often overlooked factor: the optimization of hydrolysis across different raw materials.

As a full-spectrum peptide manufacturer, standard-setter in China’s peptide industry, and holder of numerous small-molecule peptide patents, our technical team has mastered the art and science of tailoring enzymatic hydrolysis to diverse raw materials. This article explores how source-specific hydrolysis optimization enables high bioactivity, superior absorption, and consistent quality—crucial for any brand aiming to lead in the functional ingredient space.

Why Hydrolysis Matters in Functional Peptide Production

Hydrolysis—the process of breaking down proteins into peptides using enzymes—is the core technology behind bioactive peptide manufacturing. The hydrolysis strategy affects:

- Peptide molecular weight and chain length

- Functional group exposure (e.g., ACE-inhibitory, antioxidant)

- Bitterness levels

- Absorption and bioavailability in the human body

In today’s competitive B2B peptide supply landscape, brands expect more than generic hydrolysates. They demand ingredients with precise biofunctional performance, verified by science and tailored to application needs [1]. This is where hydrolysis optimization becomes a key differentiator.

Core Parameters That Influence Enzymatic Hydrolysis

Achieving targeted peptide profiles requires fine-tuning multiple variables:

- Enzyme selection: Alkaline protease, papain, trypsin, and flavorzyme are commonly used, each producing different peptide chains.

- pH and temperature control: Dictate enzyme activity and peptide release.

- Hydrolysis time: Affects degree of hydrolysis (DH), which in turn correlates with bitterness and bioactivity.

- Raw material pretreatment: Lipid removal, mineral binding, and anti-nutritional factor deactivation are often necessary.

Advanced manufacturers, like us, integrate real-time monitoring tools (e.g., HPLC, LC-MS) and automated enzymatic reactors to maintain consistency across batches while improving functional outcomes [2].

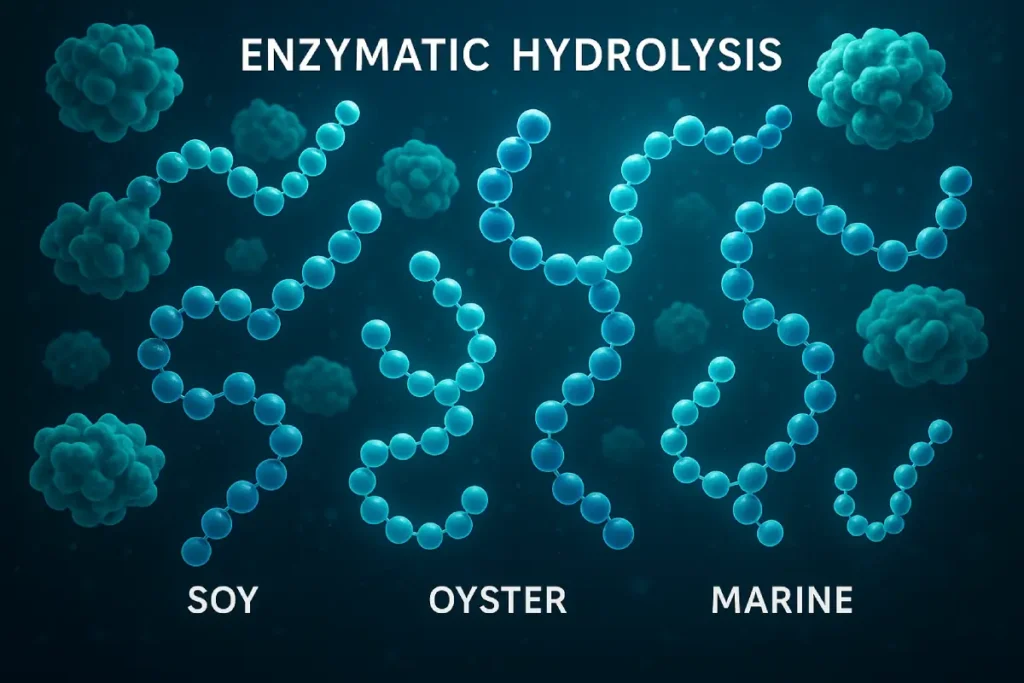

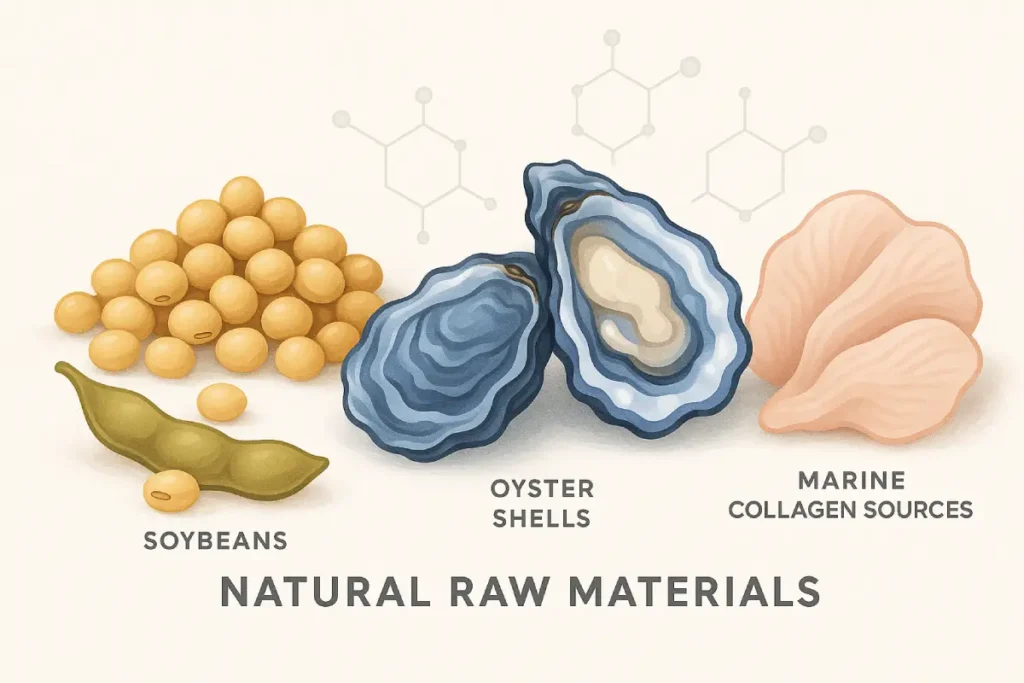

Raw Material Spotlight: Tailored Strategies for Different Protein Sources

1. Soy Protein

As a plant-based, clean-label option, soy protein is rich in essential amino acids. However, it presents challenges:

- Strong beany flavor and bitterness

- Dense globular protein structure

- Presence of anti-nutritional factors (e.g., trypsin inhibitors)

To address these, we employ a dual-enzyme system coupled with microfiltration to reduce off-flavors while maximizing bioactive peptide yield. Our patented processes have been proven to enhance the release of ACE-inhibitory peptides, supporting cardiovascular health formulations [3].

2. Bovine & Porcine Proteins

Animal-based raw materials such as bovine collagen, spleen, or porcine organs are valued for tissue-specific bioactives. However, these materials:

- Require delipidation and mineral separation

- Are susceptible to enzyme resistance due to connective tissues

- Vary in protein-to-lipid ratios

Our small peptide hydrolysis system, among the most advanced in China, allows for precision control in processing these complex matrices. This enables the production of low-molecular-weight collagen peptides (<1000 Da) and tissue-specific peptides with high bioavailability and minimal odor, ideal for joint health and recovery applications [4].

3. Marine Sources (Fish, Oyster, Krill)

Marine peptides are trending in formulations for men’s health, anti-aging, and immune modulation. Rich in trace elements and unique amino acids like taurine, marine sources offer high-value potential—but:

- Require odor control

- Are sensitive to heat and oxidation

- May accumulate heavy metals

We optimize enzymatic breakdown using cold enzymatic systems and vacuum concentration technologies, and we hold multiple patents in oyster peptide hydrolysis and mineral coordination. These processes enhance peptide–zinc binding and antioxidant capacity, ensuring superior efficacy in target applications [5].

Advanced Hydrolysis Technologies: From Enzymes to Fermentation

Modern peptide production is moving beyond single-enzyme methods. We integrate:

- Sequential enzyme hydrolysis: Targeting multiple cleavage points for a broader peptide spectrum

- Microbial fermentation (e.g., with Lactobacillus plantarum): Enhancing functional synergy, gut compatibility, and sensory properties

- Ultrafiltration and nanofiltration: For precise molecular weight selection

- Bitterness masking technologies: To improve palatability in ready-to-drink formats

These methods are applied across our 100+ peptide categories, enabling clients to meet both regulatory and functional benchmarks across the sports, clinical, and wellness nutrition sectors.

Case Study Insights: Results from Custom Optimization

Case 1: Oyster Peptide for Male Vitality

Case 1: Oyster Peptide for Male Vitality

A European brand required a high-zinc, low-odor peptide for men’s health. Using our patented enzymatic–chelating hydrolysis, we enhanced zinc retention by 2.3x and reduced trimethylamine levels by 68%, resulting in a commercially successful RTD product line.

Case 2: Soy-Oyster Dual Peptide for Cardio Support

Case 2: Soy-Oyster Dual Peptide for Cardio Support

We co-developed a dual-origin peptide blend combining plant-based ACE-inhibitory peptides and marine-derived antioxidant peptides. This solution, based on our modular enzyme platform, is now integrated into functional powder formulations across Asia and North America.

These examples reflect how B2B peptide innovation must rely on raw material–specific hydrolysis pathways and cross-disciplinary process integration.

Why Partner With a Full-Spectrum Peptide Manufacturer?

As a pioneer and patent leader in China’s peptide industry, our company offers:

- Full-spectrum peptide portfolio covering soy, oat, marine, bovine, porcine, and more

- Custom hydrolysis optimization based on enzyme library, bioreactor systems, and fermentation capabilities

- Industry-standard setting: We participate in national formulation standards and maintain global regulatory alignment (GMP, ISO, HACCP, etc.)

- R&D integration: Real-time testing and co-development for functional claims

Whether you’re formulating for cardiovascular health, gut microbiota modulation, skin support, or clinical nutrition, we provide tailored peptide ingredients backed by robust science and precision manufacturing.

Conclusion: Hydrolysis as a Competitive Advantage

In the future of functional nutrition, hydrolysis is no longer just a production step—it’s a product design tool. By optimizing hydrolysis according to raw material properties, brands can unlock unique health benefits, cleaner labels, and superior customer experiences.

Partner with a manufacturer who doesn’t just follow standards—but helps set them. Let’s co-create the next generation of bioactive peptide solutions with the power of enzymatic precision and raw material intelligence.

💡 Ready to Optimize Your Peptide Formulations?

As a full-spectrum peptide manufacturer and China's peptide industry standard setter, PEPDOO® delivers patented hydrolysis solutions for soy, oyster, marine collagen and more. Let us help you enhance bioactivity, consistency, and absorption.

🔗 Contact Us for Custom SolutionsFAQ

Combining these three peptide sources allows manufacturers to create synergistic formulations that support cardiovascular health, joint function, reproductive vitality, skin structure, and muscle recovery in a single blend. This strategy improves ingredient efficiency, cost-performance ratio, and market differentiation.

Yes. Thanks to advancements in peptide hydrolysis and spray-drying technology, our peptide blends—derived from soy, oyster, and collagen—exhibit high solubility, neutral taste, and low molecular weight, making them ideal for RTD beverages, sachets, and stick packs.

Absolutely. As a full-spectrum peptide manufacturer and standard-setter in China’s peptide industry, we offer customizable solutions tailored to your formulation goals—whether you’re focusing on muscle support, anti-aging, liver function, or metabolic health.

Our peptide production facilities meet ISO 22000, HACCP, FSSC 22000, Halal, and Kosher certifications. We follow international GMP standards and conduct rigorous in-house and third-party testing for heavy metals, peptides content, bioactivity, and microbiological safety.

We are a leading full-category peptide manufacturer in China, with extensive patent portfolios in small-molecule peptides, and a track record of formulating for major international brands. As a key standard-setting enterprise in the peptide industry, we offer cutting-edge hydrolysis and fermentation platforms, backed by decades of R&D experience.

Contact our formulation specialists via the inquiry form. After initial consultation, we’ll provide R&D support, sample prototyping, stability data, and technical documents to support your market registration and product launch.

References

- Hartmann, R., & Meisel, H. (2007). Food-derived peptides with biological activity: from research to food applications. Current Opinion in Biotechnology, 18(2), 163–169.

- Korhonen, H., & Pihlanto, A. (2006). Bioactive peptides: Production and functionality. International Dairy Journal, 16(9), 945–960.

- Li, G. H., Le, G. W., Shi, Y. H., & Shrestha, S. (2004). Angiotensin I–converting enzyme inhibitory peptides derived from food proteins and their physiological and pharmacological effects. Nutrition Research, 24(7), 469–486.

- Zague, V. (2008). A new view concerning the effects of collagen hydrolysate intake on skin properties. Archives of Dermatological Research, 300(9), 479–483.

- Yang, Y., & Guo, M. (2019). Bioactivities and bioavailability of bioactive peptides derived from marine proteins. Trends in Food Science & Technology, 86, 172–187.

Case 1:

Case 1: