Redefining Peptides: The Rise of Precision Enzymatic Hydrolysis

In the fast-evolving health and wellness industry, bioactive peptides have emerged as premium ingredients due to their efficacy, safety, and versatility. While enzymatic hydrolysis has traditionally been the go-to method for producing peptides, a new paradigm has emerged—precision enzymatic hydrolysis. This advanced approach enables the design of peptides with defined sequences and targeted bioactivities, aligning perfectly with the demands of next-generation functional products.

From Conventional Hydrolysis to Precision Peptide Engineering

Traditional hydrolysis methods produce random peptide fragments with broad molecular weight distributions and undefined functionality. This lack of precision limits reproducibility, formulation consistency, and ultimately, product efficacy.

At the forefront of this movement is PEPDOO®, a high-tech enterprise that has developed the proprietary OKPEP® Precision Hydrolysis Technology Platform. By integrating AI with biotechnology, PEPDOO® redefines industry standards through six pillars of precision:

- Targeted enzymatic cleavage

- Specific peptide sequences

- Accurate quantification

- Defined bioactivity targets

- Measurable functional outcomes

- Enhanced absorption efficiency

This framework allows manufacturers to go beyond hydrolysis—to actually engineer peptides by design.

The Science Behind Precision Enzymatic Hydrolysis

Enzymatic hydrolysis involves breaking down proteins into smaller peptides using specific enzymes. Factors such as enzyme type, pH, temperature, and reaction time influence the peptide profile. In conventional systems, these parameters are loosely controlled, resulting in variable outcomes [1].

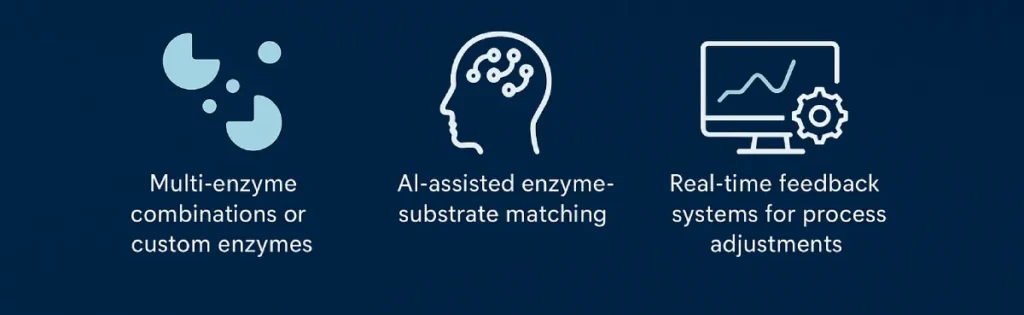

In contrast, precision enzymatic hydrolysis focuses on controlling every variable. Key innovations include:

- Multi-enzyme combinations or custom enzymes

- AI-assisted enzyme-substrate matching

- Real-time feedback systems for process adjustments

These technologies ensure consistent production of bioactive peptides with known structures and functions.

Structure Determines Function: Why Peptide Sequence Matters

The bioactivity of a peptide is determined by its amino acid sequence. Research shows that specific sequences are associated with distinct physiological benefits. For example:

- Pro-Hyp-Gly, a tripeptide found in collagen hydrolysates, promotes skin regeneration and hydration [2].

- IPP and VPP, milk-derived tripeptides, support blood pressure regulation via ACE inhibition [3].

- Glutamine-rich oligopeptides enhance gut barrier integrity and modulate immune response [4].

Conventional hydrolysis does not guarantee these peptides will be present. But with precision hydrolysis, manufacturers can intentionally generate targeted sequences, improving both functionality and reliability.

Molecular Weight and Bioavailability

Short-chain peptides—especially those under 1,000 Daltons—are more easily absorbed in the human body. They cross the intestinal barrier more efficiently and enter systemic circulation faster than longer chains [5].

PEPDOO®’s OKPEP® platform is designed to produce:

- Low-molecular-weight peptides for rapid absorption

- Function-specific fractions with tight MW distribution

- Optimized solubility and stability for different delivery formats

- High-purity peptide concentrates ideal for formulation flexibility

Whether for drinks, capsules, sachets, or gummies, precision matters for performance.

Analytical Tools for Designing Precision Peptides

Cutting-edge analytical techniques ensure every peptide meets rigorous quality and function benchmarks:

- HPLC and LC-MS/MS for purity, sequencing, and MW profiling

- MALDI-TOF-MS for fast fingerprinting

- Bioinformatics and peptide databases to map sequence–activity relationships

- AI-driven algorithms to predict and refine functional outcomes

These tools form the backbone of PEPDOO®’s process intelligence, ensuring each product delivers predictable and consistent results.

Application Areas: Precision with Purpose

Precision peptide manufacturing empowers product innovation across several high-growth markets:

1. Health & Functional Nutrition

Peptides with targeted effects for immune support, antioxidant activity, sleep improvement, and metabolic health.

2. Medical Nutrition (FSMP)

Highly digestible peptides for special diets including hypoallergenic, post-operative, and elderly formulations.

3. Beauty-from-Within

Collagen tripeptides, elastin peptides, and anti-glycation peptides for skin firmness, hydration, and youthful appearance.

4. Sports Nutrition

Fast-acting peptides for muscle synthesis, endurance, and post-exercise recovery.

🎯 As a pioneer in this space, PEPDOO® combines scientific peptide sequencing with global market insight to provide B2B clients with high-performance peptide ingredients that are “precisely designed, functionally targeted, rapidly absorbed, and sensorially impactful.” The brand has served clients across five continents and actively contributes to the formulation of peptide industry standards.

From Lab to Commercial Scale: Ensuring Industrial Consistency

Scaling precision peptide production comes with its own challenges—batch consistency, cost control, and quality retention being the most critical. PEPDOO® addresses these through:

- Continuous-flow multi-stage enzyme reactors

- AI-powered enzyme utilization and recycling

- Integrated Process Analytical Technology (PAT)

- Scalable filtration, concentration, and spray-drying solutions

Regulatory and Quality Control Standards

Global B2B buyers demand not just performance but also safety and compliance. PEPDOO® adheres to:

- GMP, HACCP, and ISO 22000 manufacturing standards

- Regulatory approvals for GRAS (US), Novel Food (EU), and ASEAN compliance

- Clean-label, allergen-free, and vegan-friendly solutions where needed

- Full traceability and batch documentation for export markets

Looking Ahead: The Future of Peptide Innovation

The next frontier of precision peptide development will be powered by:

- AI-guided peptide discovery and predictive modeling

- Synthetic biology for novel enzyme creation

- Microbiome-targeted peptides for gut, brain, and immune health

- Personalized peptide formulation based on omics data

PEPDOO® continues to invest in these areas to offer forward-looking solutions to its global partners.

Conclusion: Partner with PEPDOO® for Precision, Performance, and Possibility

Precision enzymatic hydrolysis is more than just a method—it is a philosophy for building peptide ingredients that are effective, reliable, and market-ready.

✅ Whether you’re formulating a gut health beverage, a dermal collagen booster, or a clinical peptide blend, PEPDOO® is your trusted partner in custom peptide innovation.

Let’s move from random hydrolysates to data-driven, functional peptide design—with science and precision at every step.

👉 Contact PEPDOO® to create your next-generation peptide product today.

Frequently Asked Questions

It is an advanced technique that uses specific enzymes and controlled reaction conditions to produce peptides with defined sequences and targeted bioactivities.

Unlike traditional hydrolysis, which yields random peptide mixtures, precision hydrolysis allows for tailored peptide production, improving consistency and biofunctionality.

They offer enhanced efficacy, improved stability, and targeted health functions—ideal for use in functional foods, nutraceuticals, cosmetics, and pharmaceuticals.

Yes, our proprietary OKPEP® platform enables custom peptide design aligned with your formulation goals, bioactivity needs, and market application.

References

- Korhonen, H., & Pihlanto, A. (2006). Bioactive peptides: Production and functionality. International Dairy Journal, 16(9), 945–960.

- Zague, V., et al. (2018). Collagen peptides modulate the metabolism of extracellular matrix in dermal fibroblasts. Journal of Dermatological Science, 90(3), 216–224.

- Nakamura, Y., et al. (1995). Antihypertensive effect of sour milk and peptides isolated from it that are inhibitors to angiotensin I-converting enzyme. Journal of Dairy Science, 78(6), 1253–1257.

- Udenigwe, C. C., & Aluko, R. E. (2012). Food protein-derived bioactive peptides: Production, processing, and potential health benefits. Journal of Food Science, 77(1), R11–R24.

- Shimizu, M. (2004). Food-derived peptides and intestinal functions. BioFactors, 21(1–4), 43–47.