1. The Rise of Pea-Derived Proteins in Functional Nutrition

In recent years, pea-derived ingredients have gained remarkable traction in global functional nutrition, driven by plant-based trends, sustainability goals, and clean-label preferences. Both pea protein and pea peptide are extracted from yellow peas (Pisum sativum), yet their nutritional and functional profiles differ significantly.

For B2B buyers—from functional food and dietary supplement brands to medical nutrition developers—understanding these differences is crucial for product formulation, efficacy, and market positioning. This article compares pea protein and pea peptide from a technological and commercial perspective, helping procurement, R&D, and marketing professionals make informed sourcing decisions.

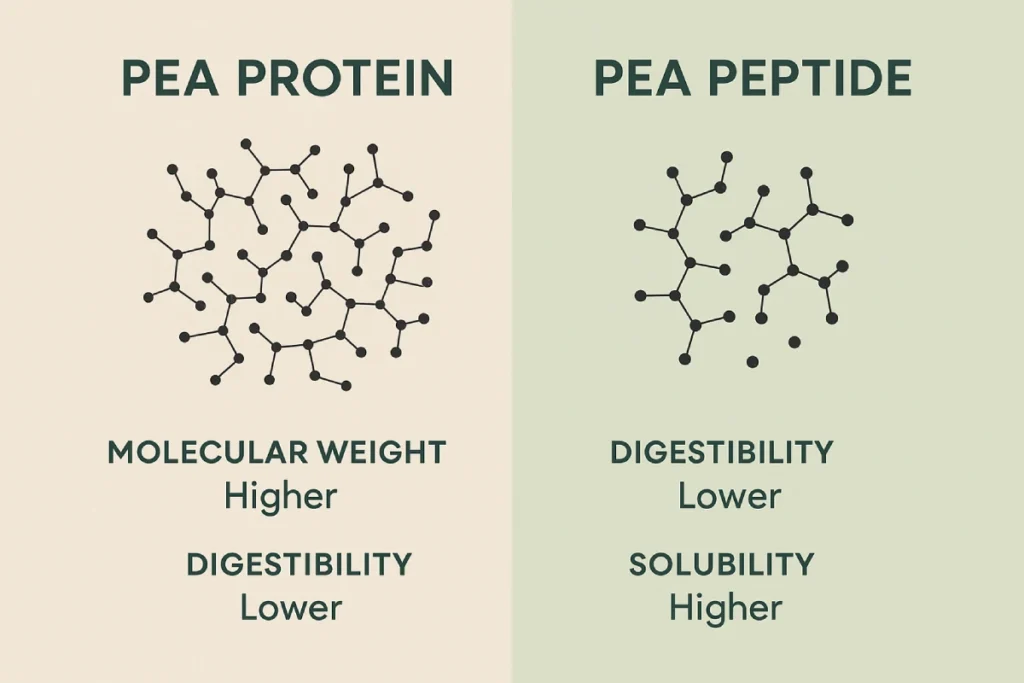

2. Understanding the Difference: Structure & Function

2.1 Pea Protein — The Conventional Option

Pea protein isolate is produced through mechanical and enzymatic extraction processes, yielding a product with around 80–85% protein content. It provides a balanced amino acid profile, especially rich in lysine and arginine, and serves as a plant-based protein source in shakes, bars, and plant-meat analogues [1].

However, its large molecular structure (typically >10 kDa) means slower digestion and potential solubility issues. In beverage or RTD formulations, pea protein often causes sedimentation, chalky mouthfeel, or beany flavor.

2.2 Pea Peptide — The Next Generation Ingredient

Pea peptide, in contrast, is derived from controlled enzymatic hydrolysis of pea protein. This process breaks long peptide chains into bioactive oligopeptides (<1,000 Da), enhancing solubility, absorption, and functionality [2].

These short-chain peptides are readily absorbed by the small intestine, bypassing conventional digestion, resulting in faster bioavailability and targeted physiological benefits such as anti-inflammatory, antioxidant, and metabolic modulation effects [3].

For product developers, this translates into improved stability, taste, and bioefficacy—attributes increasingly demanded in functional beverages, clinical nutrition, and sports recovery products.

3. Hydrolysis Technology & Digestibility: Why It Matters

The performance of pea peptides largely depends on hydrolysis optimization—the precision control of enzyme type, hydrolysis time, temperature, and pH. Studies show that peptides with a degree of hydrolysis (DH) between 10–20% exhibit the highest antioxidant activity and solubility [4].

Advanced manufacturers like PEPDOO® apply multi-enzyme hydrolysis combined with controlled fermentation technology, ensuring uniform molecular weight distribution and enhanced bioactivity. Compared to standard hydrolyzed plant proteins, PEPDOO®’s proprietary process produces low-bitter, high-stability peptides suitable for sensitive applications like enteral nutrition and nutraceuticals.

This technological precision also guarantees batch-to-batch consistency, a key factor for B2B buyers focusing on quality control and regulatory compliance.

4. Bioavailability and Functional Efficacy

Bioavailability is a critical differentiator between pea protein and pea peptide. Whole proteins must be broken down by digestive enzymes, whereas small peptides are absorbed directly through peptide transporters (PepT1) in the intestinal wall [5].

Scientific studies demonstrate that pea-derived peptides exhibit antioxidant, lipid-regulating, and glucose-lowering properties, making them ideal for metabolic health formulations [6]. Peptide fractions rich in hydrophobic amino acids also promote satiety signaling and muscle recovery, expanding their use in sports and weight-management products [7].

In contrast, pea protein primarily serves as a macronutrient for general protein fortification, not as a bioactive ingredient.

5. Sensory and Application Differences

From a formulation standpoint, pea peptides excel where taste, solubility, and dispersibility matter most.

| Feature | Pea Protein | Pea Peptide |

|---|---|---|

| Molecular Weight | 10–100 kDa | <1 kDa |

| Solubility | Limited (especially in acidic systems) | High (across pH range 2–10) |

| Taste | Earthy, beany, slightly bitter | Mild, clean taste (after enzymatic debittering) |

| Applications | Protein powders, bakery, plant meats | Functional beverages, dietary supplements, enteral nutrition |

This sensory advantage makes pea peptides ideal for ready-to-drink (RTD) formulations, functional gummies, and clinical nutrition blends where consumer experience is key.

6. Market Trends: The Shift Toward Bioactive Peptides

According to the Global Market Insights report (2024), the plant peptide segment is expected to grow at a CAGR of 11.5% between 2024 and 2030, outpacing traditional plant proteins [8].

Driving factors include:

- Rising demand for functional foods targeting gut, skin, and metabolic health

- Increasing adoption of bioactive ingredients supported by scientific data

- Shift from “macronutrient-based” to “function-based” product claims

For B2B brands, the transition to pea peptides is more than a formulation choice—it’s a market positioning strategy that aligns with evidence-based nutrition trends.

7. Case Studies: Successful Applications

Case 1 — Functional Beverage Brand (Japan)

A leading Japanese functional beverage company replaced 40% of pea protein with PEPDOO® Pea Peptide to improve solubility and reduce sedimentation. The reformulated drink achieved 30% higher protein digestibility, a cleaner flavor profile, and a 20% increase in consumer repurchase rate within three months.

Case 2 — Sports Nutrition Company (Europe)

A sports nutrition brand in Germany integrated pea peptide concentrate (MW <800 Da) into a post-workout formulation. The result: faster muscle recovery, reduced digestive discomfort, and a 10% reduction in ingredient costs due to improved protein utilization efficiency.

Case 3 — Clinical Nutrition Brand (China)

A domestic medical nutrition enterprise co-developed a diabetic-friendly peptide formula with PEPDOO®, leveraging its patented enzymatic hydrolysis process. The final product showed significant blood glucose control improvements in pilot studies, now under CFDA registration.

These cases highlight how technological partnerships with peptide-focused manufacturers can deliver tangible functional and commercial value.

(PEPDOO® can provide anonymized technical reports and pilot study summaries to qualified B2B partners for due-diligence.)

8. Why Partner with PEPDOO®

PEPDOO® is more than a pea peptide manufacturer—it is a comprehensive peptide solution provider. As China’s peptide industry standard-setter and a leader in small-molecule peptide patents, PEPDOO® integrates scientific research, precision hydrolysis, and scalable manufacturing to serve global functional food and supplement brands.

Key advantages include:

- Full-spectrum peptide production: covering plant, marine, animal, and microbial sources

- Proprietary enzyme & fermentation systems for enhanced functionality

- ISO, HACCP, and FSSC22000 certified facilities ensuring international compliance

- Co-development support for custom peptide formulations and application testing

For B2B buyers, partnering with PEPDOO® means access to next-generation bioactive ingredients with reliable supply, consistent quality, and scientific credibility.

9. Regulatory and Supply Chain Considerations

Pea peptides generally hold GRAS status (U.S.) and comply with EU Novel Food regulations when produced through standardized enzymatic processes. However, brands should ensure:

- Transparent traceability and ingredient documentation

- Verification of amino acid composition and purity

- Consistent batch certification and microbial safety testing

PEPDOO® maintains full traceability from raw pea sourcing to peptide fractionation, providing COA, MSDS, and stability data—critical for B2B compliance and global export.

10. Key Takeaways for B2B Buyers

| Consideration | Pea Protein | Pea Peptide |

|---|---|---|

| Absorption Speed | Moderate | Fast |

| Bioactivity | Nutritional | Functional (metabolic, antioxidant) |

| Taste & Solubility | Grainy, limited | Smooth, stable |

| Suitable for | Basic nutrition | Functional & medical nutrition |

| Market Growth | Mature | Rapidly expanding |

In essence, pea peptides represent the functional evolution of pea protein—offering not just protein content but targeted physiological efficacy. For brands seeking differentiation, clean-label performance, and technical reliability, bioactive peptides are the future.

11. Conclusion: Why Pea Peptides Are the Future for Functional Nutrition Brands

The comparison between pea protein and pea peptide reflects a broader industry shift—from nutrition quantity to functionality quality. While pea protein remains a valuable commodity, pea peptides unlock new value through enhanced digestibility, stability, and biological activity.

As functional food and supplement markets evolve, partnering with a scientifically driven, technologically advanced manufacturer becomes essential.

PEPDOO® empowers global B2B partners to co-develop innovative, evidence-backed, and scalable functional peptide ingredients, helping brands move from protein-based formulations to bioactive nutrition solutions.

Unlock the Potential of Pea Peptides for Your Brand

Partner with PEPDOO®, China’s peptide industry standard-setter and patent leader. Co-develop full-spectrum functional peptide ingredients with scalable production, scientific validation, and technical support—turning protein-based formulations into bioactive nutrition solutions.

Request Technical ConsultationFAQ

A: Pea protein is a high-molecular-weight ingredient (~10–100 kDa) suitable for general protein fortification, while pea peptides are enzymatically hydrolyzed (<1 kDa) bioactive fragments. Pea peptides offer faster absorption, higher solubility, and functional benefits such as antioxidant, anti-inflammatory, and metabolic support. Choosing peptides can improve product performance, sensory quality, and functional positioning.

A: Lower molecular weight in pea peptides allows direct absorption through intestinal peptide transporters, bypassing digestion. This increases bioavailability and targeted physiological effects, making pea peptides ideal for clinical nutrition, functional beverages, and sports supplements. PEPDOO® ensures consistent low molecular weight distribution for reliable product performance.

A: Yes. Unlike pea protein, which may be chalky or bitter, pea peptides have high solubility and a clean taste due to advanced enzymatic hydrolysis and debittering processes. B2B developers benefit from easy incorporation into RTD beverages, gummies, and enteral nutrition formulas without compromising texture or stability.

A: Pea peptides generally hold GRAS status (U.S.) and comply with EU Novel Food regulations. B2B buyers should request COA, MSDS, and stability data to ensure quality and traceability. PEPDOO® provides full documentation and batch-to-batch consistency, supporting global regulatory compliance.

A: Collaborating with PEPDOO®, a full-spectrum peptide manufacturer and China’s industry standard-setter, provides custom peptide formulation support, scalable production with consistent quality, access to patented hydrolysis and fermentation technologies, and technical guidance for functional claims. This helps B2B brands accelerate innovation, improve efficacy, and differentiate products.

A: Yes, PEPDOO® has partnered with brands globally: a Japanese beverage improved protein digestibility and flavor by replacing 40% pea protein with pea peptides; a German sports brand achieved faster muscle recovery and reduced digestive discomfort; a Chinese clinical nutrition enterprise co-developed a diabetic-friendly peptide formula, demonstrating blood glucose regulation in pilot studies.

A: While pea peptides may have a higher raw material cost, their higher bioactivity, absorption, and functional efficacy can reduce required dosages, improve product performance, and increase consumer satisfaction and repeat purchase rate, leading to overall cost efficiency in formulation.

References

- Tang, C. H., & Ten, Z. (2020). Pea protein isolate: Production, properties, and applications. Food Hydrocolloids, 101, 105–118.

- Mäkinen, O. E., & Arendt, E. K. (2021). Plant protein hydrolysates: Processes, properties, and applications. Trends in Food Science & Technology, 109, 291–306.

- Li, Y., & Yu, J. (2023). Bioactive peptides from legumes: Functional properties and health benefits. Journal of Functional Foods, 99, 105–146.

- Xu, Z., et al. (2022). Degree of hydrolysis and antioxidant activity of pea protein hydrolysates. Food Chemistry, 384, 132–144.

- Brandsch, M. (2020). Transport of peptides across the intestine. Physiological Reviews, 100(1), 611–643.

- Ma, Y., & Wu, J. (2023). Pea peptide fractions regulate lipid metabolism in high-fat diet mice. Nutrients, 15(2), 240.

- Hou, Y., et al. (2021). Small peptides from legumes: Satiety and muscle recovery implications. Food Research International, 147, 110–125.

- Global Market Insights. (2024). Plant Protein and Peptide Market Report 2024–2030.